Oleh Petrenko took charge of the state enterprise Drohobych Saltworks in 2021. Before then, he worked in the civil society sector as a lawyer, defending the company in court from 2017 to 2020. When he finally took the helm, one of his first steps was launching a branding competition. Soon after, the team introduced premium flake salt, spiced salt, and a line of merchandise. Production quadrupled. Earnings shot up a hundredfold.

Now Petrenko is working on a far more ambitious project: modernizing the entire plant and turning it into a place for recreation and treatment.

YBBP journalist Artem Moskalenko visited Drohobych to learn how the operation went from stagnation to profit, what gives the local salt international potential, and how it is adapting to the export ban.

A story rooted in childhood

Petrenko is forty-one. Short in stature, he wears jeans and a black hoodie printed with a collage of Ivan Franko riding a bicycle and carrying salt. It is part of the Drohobych Saltworks’ merchandise. He wears it often, always ready to tell people about the enterprise.

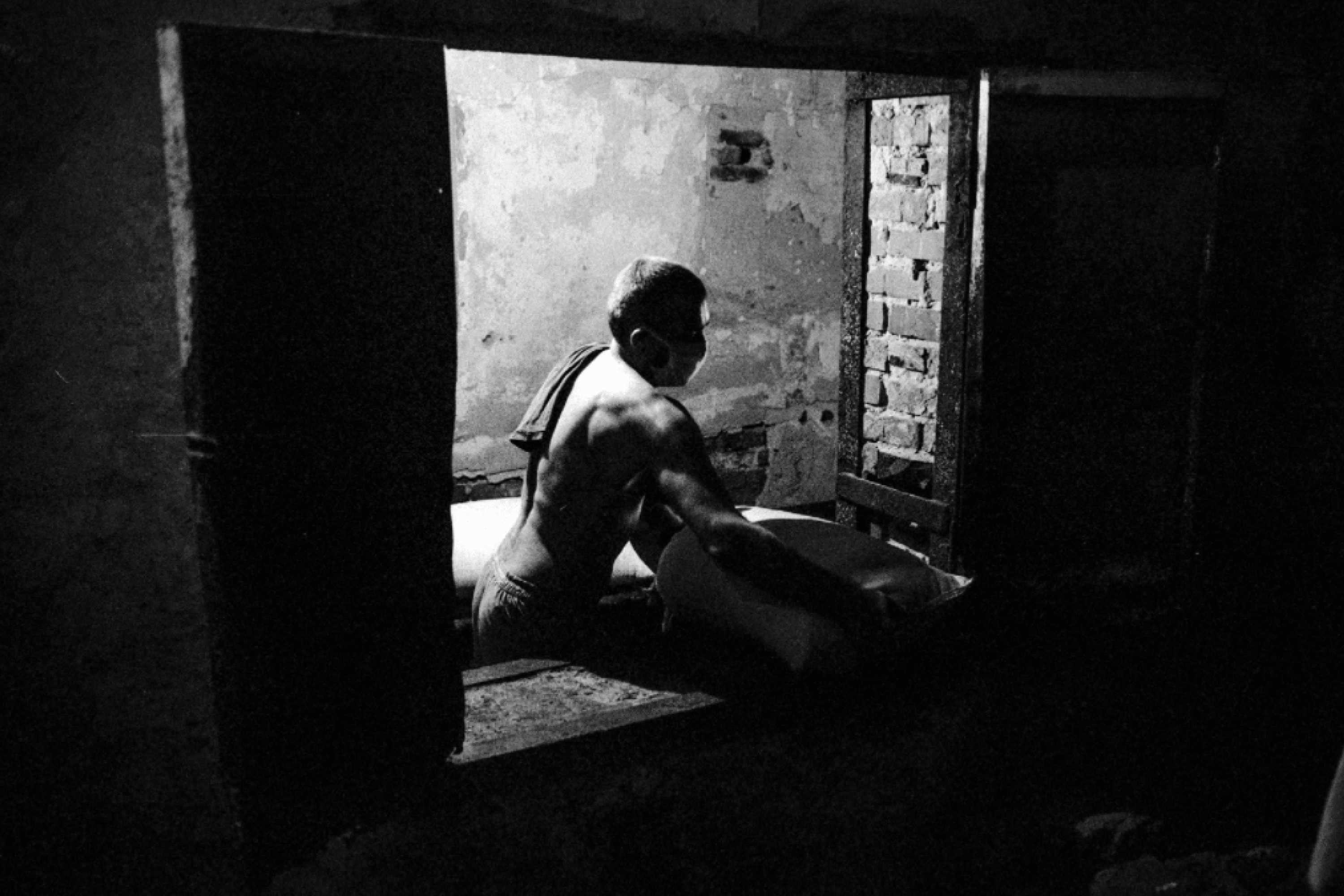

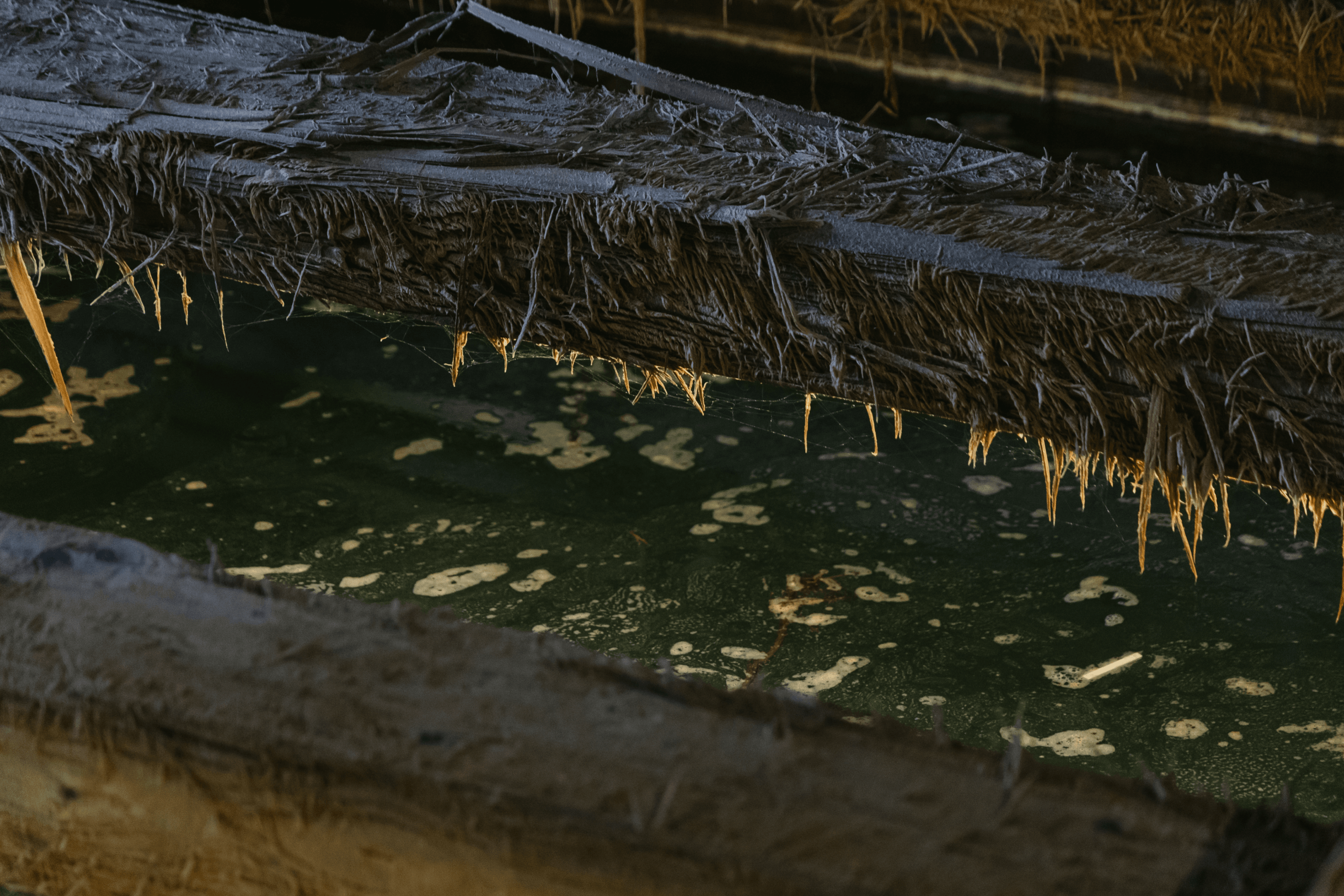

He grew up just a few minutes’ walk away. On his daily route to school, he would pass by and watch craftsmen collect and evaporate brine, a solution with a high salt content. The scale of what was happening there left a lasting impression.

“Back then, everything seemed bigger,” he says. “Maybe because I was smaller. And the place felt more alive. Even old photographs show how carefully it was maintained.”

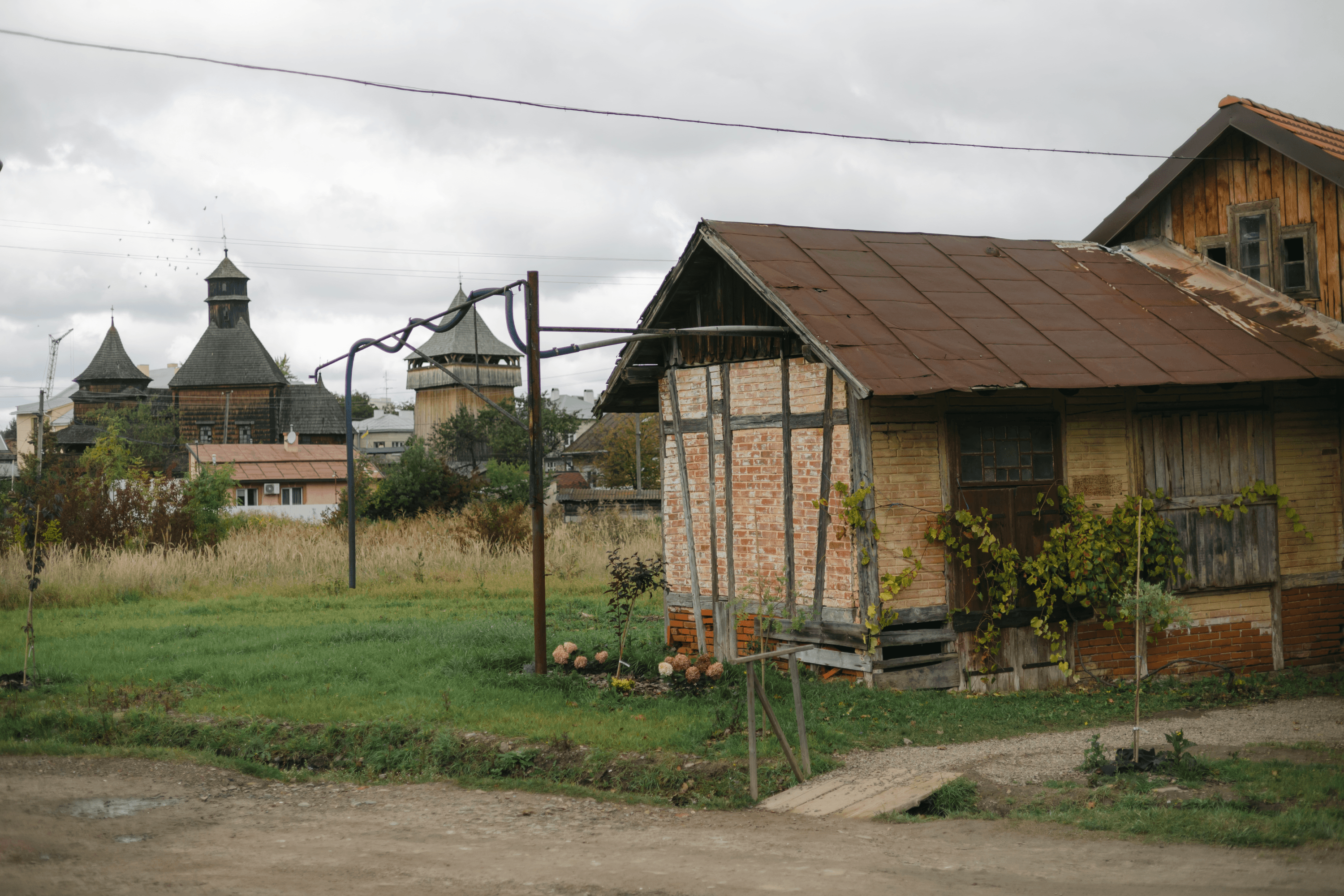

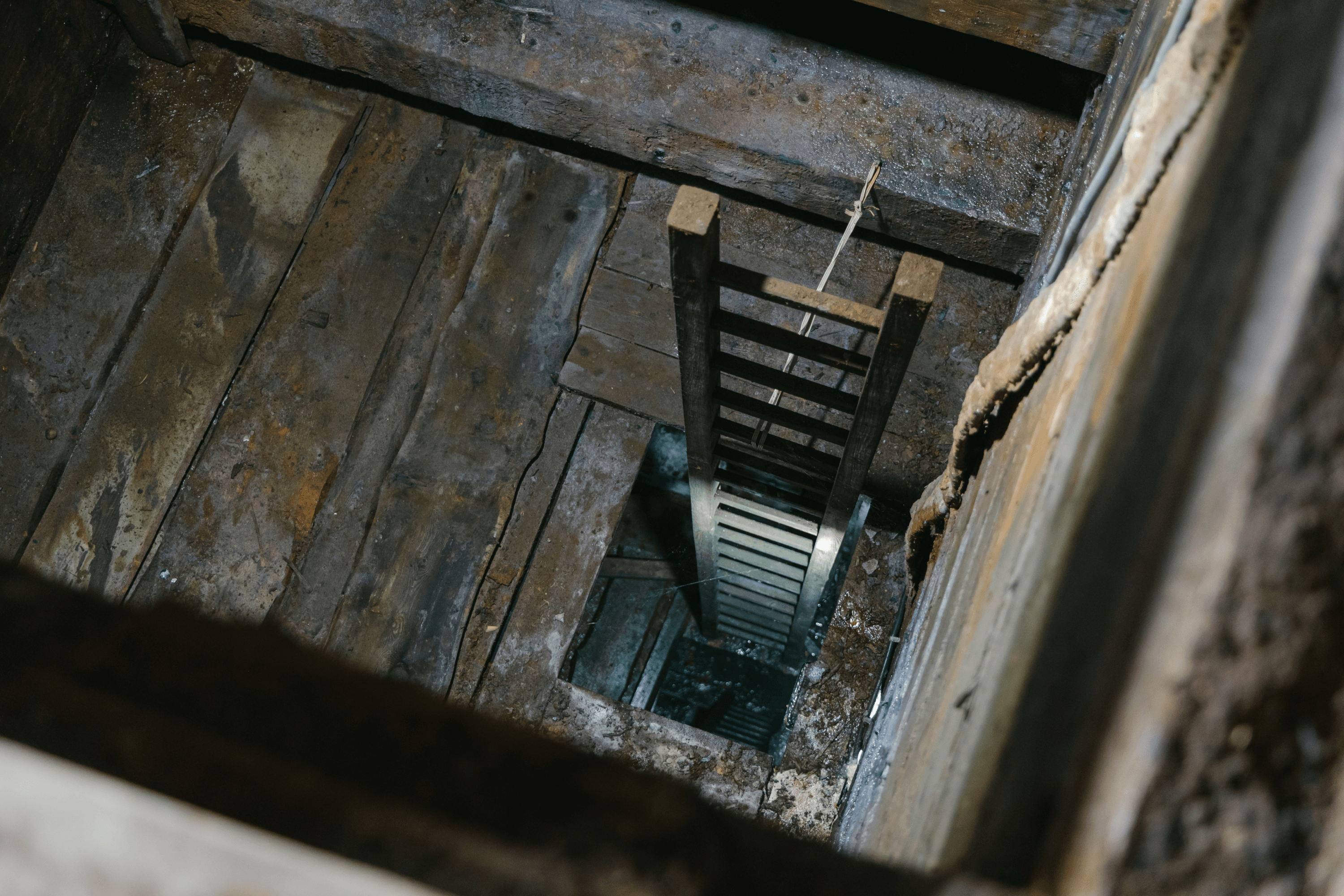

With time, the operation slipped into decline. Output began to shrink, and the buildings crumbled. Several historic structures that once formed its core suffered the most, including the former director’s house, an architectural monument of local significance. As a child, Oleh used to gather there with friends on its veranda. Today, only the foundation and fragments of walls remain.

However, archival photographs and old drawings have survived, making restoration technically possible. It would require substantial investment, but he believes the area can be brought back to life. “There’s a small stage there,” he adds. “It would be ideal for cultural events or city celebrations.”

Trained as a lawyer, Petrenko worked in local self-government bodies and ran for city council twice without success. Together with fellow activists, he co-founded the NGO Halytska Varta, which monitored the work of local authorities and carried out investigations. He worked with documents and later obtained an attorney’s license.

In 2018, the State Labour Service of Ukraine informed the company that its operations would be suspended after inspectors were denied access during a check. Acquaintances asked him to represent the business in court. The case lasted three years.

In 2021, the dispute was finally resolved in favour of the saltworks. Soon after, the State Property Fund of Ukraine announced a competition to appoint a new head of the facility. Friends encouraged him to apply. “They believed I could not only keep it afloat but also give it new momentum,” he says.

He already had a plan to restore the plant and develop not only production, but also tourism, recreation, and medical services. “I opened my laptop and showed the project and visualisations,” he recalls. “The commission was impressed. Their eyes lit up, even though we couldn’t display the presentation on a projector and had to review everything on the laptop screen.”

That is how, in 2021, Oleh Petrenko became the director of the Drohobych Saltworks.

The first year on the job

The first days were difficult, as the staff did not yet trust him. Many believed he had arrived on behalf of local authorities to shut down production and turn it into a tourist attraction. “Officials have always seen this place primarily as a tourist destination,” Petrenko says. “But for the workers, the product itself matters. They wanted to keep making salt.”

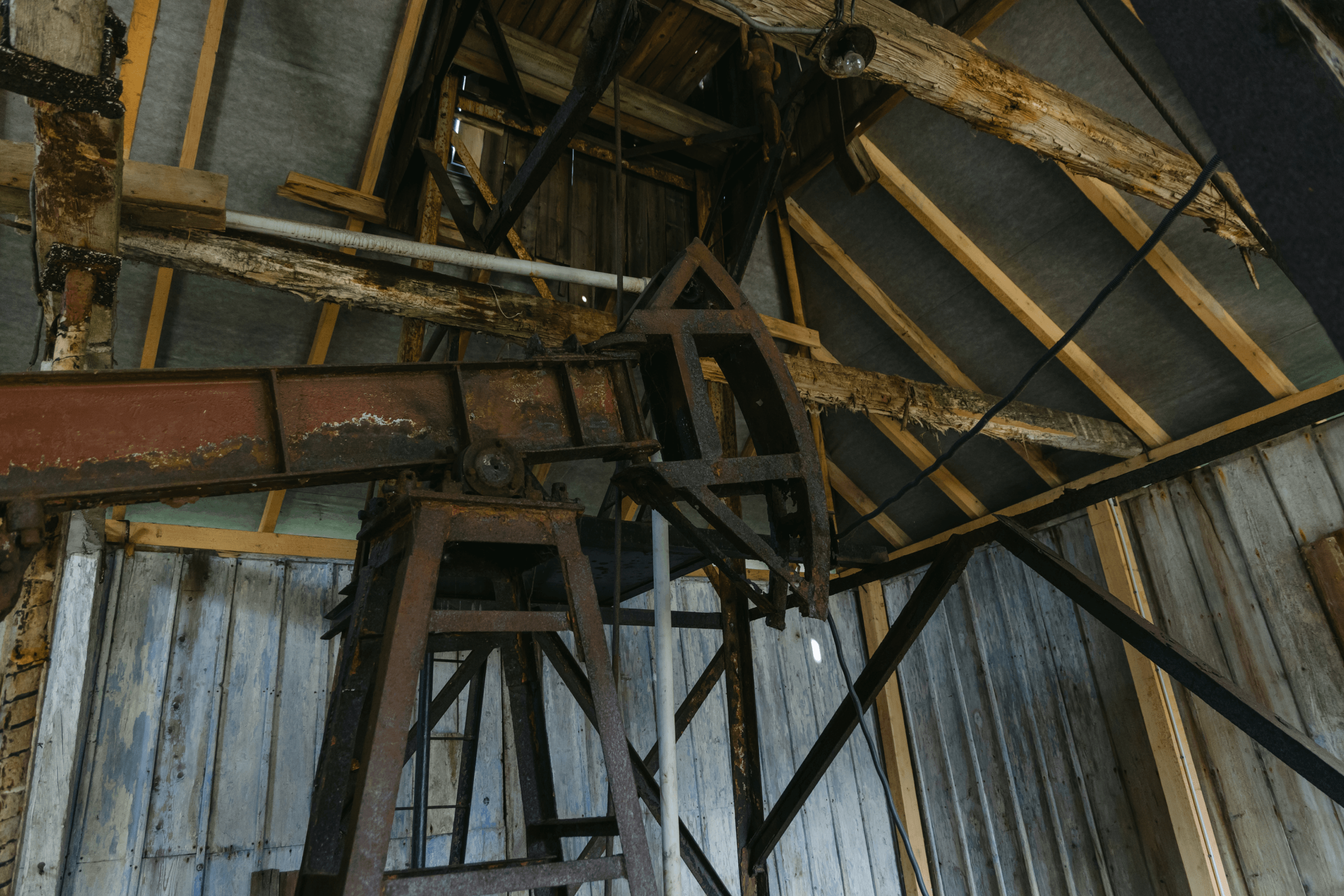

Money was tight. The business was not operating at a loss, but income barely covered wages and basic expenses. Quarterly profits ranged from ₴20,000 to ₴60,000, depending on the season. One of the first practical steps after Petrenko’s arrival was the installation of a new salt pan, a large metal vessel in which brine slowly evaporated over wood. This increased monthly output from 15 tons to 20–25.

The team also began actively promoting the product and reaching out to major retail chains. At the time, Artemsil was still operating, and competing with Bakhmut salt posed a real challenge. Evaporated salt costs far more to produce than mined rock salt and is therefore priced at roughly three times as much. For this reason, Petrenko initially focused on local retailers. By February 2022, an agreement had been reached with the Silpo chain, which was ready to distribute the salt nationwide. However, Russia’s full-scale invasion prevented the plan from being implemented.

Work on the brand moved forward in parallel. A volunteer logo competition brought in thirteen proposals, three of which stood out. The winning design was selected by a commission that included representatives of the State Property Fund, regional and city authorities, and civil society.

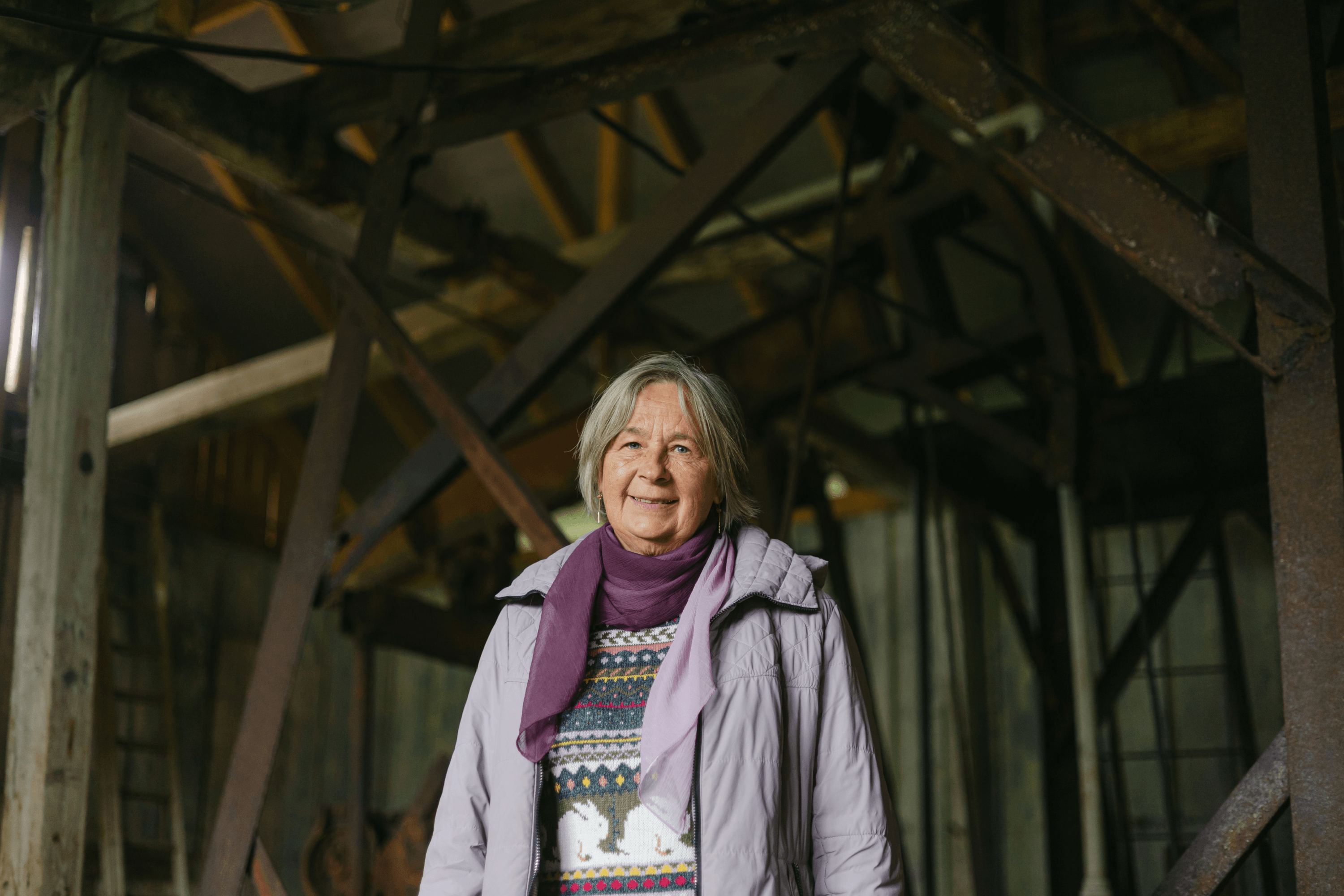

Around the same time, the trademark “Drohobych Saltworks” was registered and the souvenir shop was renovated. “We’d always had a shop in some form,” Petrenko says. “Our technologist, Ms. Oksana, made decorative salt figurines. Later, Oleksandr, a marketer from the municipal tourism department, suggested taking the shop further. Together, they developed a new range of merchandise that included different types of salt, mugs, T-shirts, bath bombs, and other items, and moved the shop to a new space.

Today, it functions as a separate business leasing space on the premises. The company supplies the salt, while the shop owner pays both for the products and for the right to use the brand. This model brings additional income and visibility, while visitors can buy souvenirs made on site.

In 2021, a small batch of local salt was shipped to the United States. The opportunity came through partners who had long been exporting Ukrainian tea and already had logistics in place. “They suggested buying a ton and handling the shipment themselves,” Petrenko recalls. “We had enough stock, so that wasn’t a problem. The profit was limited, since the sale went through intermediaries. But seeing our salt reach America was something special. And I know it is sold there.”

All plans had to be suspended on February 24, 2022.

Salt imports instead of exports

When the invasion began, Oleh Petrenko joined a local Territorial Defense unit. He initially remained in the city, helping with organization, coordinating humanitarian aid, and staying in touch with supporters. Later, he was deployed east, near Soledar.

“I spent two or three months right on the front line,” he says. “Officially, I was a clerk, but in wartime that role is only nominal. Today you’re a clerk, tomorrow you’re in a trench. Everyone understood that anyone could be sent forward if there were not enough people,” he recalls. “There were no drones then. The war was completely different. Terrifying, but different.” Despite his service, Petrenko continued to manage the saltworks remotely. Whenever possible, he called his deputy to discuss decisions and offer guidance.

In April 2022, Artemsil stopped mining in Soledar. Before the invasion, the plant had supplied nearly all of Ukraine’s demand for table salt, producing around 450,000 tons a year. In May, operations had ceased entirely. Shelling destroyed workshops and equipment, buildings were left in ruins, and workers were evacuated. By summer, the city had become a major battleground, and since January 2023 it has been under Russian occupation.

Almost overnight, Ukraine was forced to shift from exporting salt to importing it. Emergency agreements with Romania, Turkey, and Egypt helped avert shortages.

“There was a moment when Donetsk salt was already gone, imported supplies hadn’t arrived yet, and everyone was scrambling to find reserves inside the country. Here things became very tense. I was lucky to be closer to Soledar than to Drohobych at the time, so I didn’t have to deal with it,” Petrenko recalls with a smile. His deputy’s phone rang nonstop as officials at every level urgently searched for new sources of supply. The saltworks increased output to 60–65 tons a month. Even so, it could not match Artemsil’s scale. Donetsk salt is an industrial product, while local salt is more artisanal. At Artemsil, rock salt was extracted from ancient underground layers and naturally contained mineral impurities that give it a coarse texture and a grayish tint. Drohobych salt, by contrast, is produced by evaporating brine. It is cleaner, finer, and more delicate in taste. The process, however, is far more expensive.

At the end of 2022, Oleh Petrenko was released from military service for family reasons. His contract at the saltworks was expiring and needed to be renewed. He does not hide how difficult that choice was. Even now, he asks himself whether he should have stayed in uniform. In the end, he decided that he had to finish what he had started with the business.

Why export Drohobych salt?

Today, Petrenko’s priority lies in restoring gas supply, which was cut off back in 2013 after the enterprise fell into debt. Restarting the system would require roughly ₴2 million. It would not make production cheaper. But the process would become far more predictable. Working on gas costs about the same as working on wood, yet it removes reliance on raw materials with unstable supply and significantly simplifies day-to-day work. There is also a larger and more expensive plan: rebuilding the destroyed production hall. Bringing all the pans together in one space would make it possible to increase capacity and reduce losses. The price tag for that effort is estimated at ₴15 million.

The company is now profitable. In 2024, it earned close to ₴24 million. Even so, these funds are not enough to finance large-scale upgrades. Under Ukrainian law, state-owned enterprises must transfer a significant portion of their income to the state. For Drohobych Saltworks, that share amounts to 80 percent.

“When I started, our retained share was 20 percent of ₴60,000 per quarter,” Petrenko says. “Now it is 20 percent of ₴2 million per month. It is a positive development, but it still does not give us the freedom to invest as much as we need.”

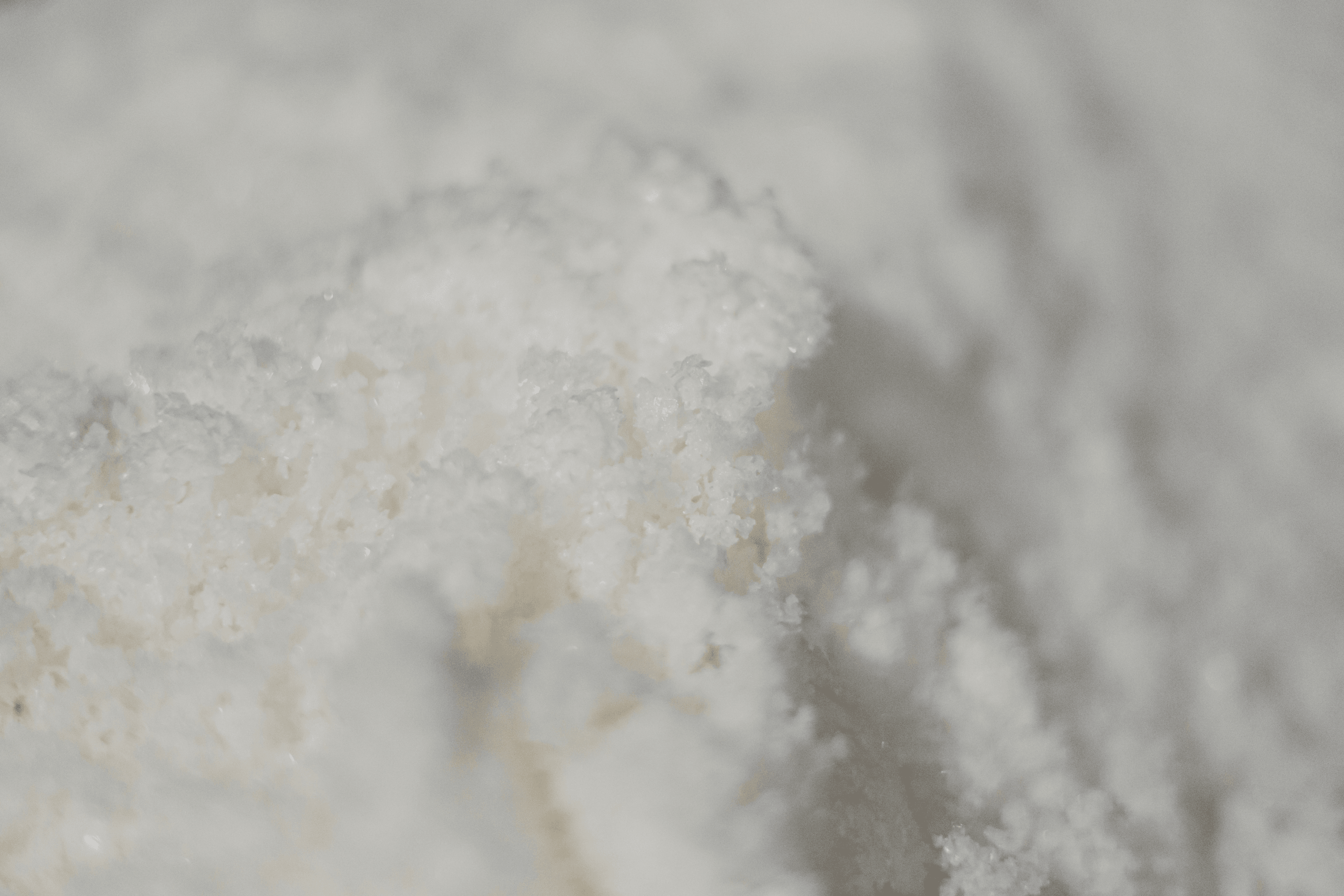

That is why his strategy is focused on value rather than volume. Petrenko is betting on premium flake salt, the structure of which is fundamentally different from that of ordinary table salt. Instead of fine grains, it forms light, snowflake-like crystals. His reference point is Maldon Salt, the English brand widely known among fine-dining chefs. “This is a completely different market,” he explains. “Chefs use this kind of salt in high-end restaurants to finish steaks, salads, and desserts. Internationally, consumers understand the difference between table salt and finishing salt. In Ukraine, this distinction still needs to be explained.”

For premium flake salt, two-thirds of the retail price is pure profit. In Ukraine, premium salt sells for about three times the price of standard salt. On international markets, Petrenko believes, it could be five times higher. Even then, Drohobych salt would remain competitive, as similar products abroad are still more expensive.

At present, the saltworks produces around one ton of premium flake salt per month. With access to export markets, output could be scaled up to ten tons a year. Independent experts support this estimate. Petrenko has already discussed these prospects with a chef and author of books on national cuisines, who has written about Ukrainian food and is now preparing titles on Germany, Estonia, and Spain. However, after Artemsil ceased operations and Soledar was occupied, the government imposed a ban on salt exports to prevent shortages. Imports have since stabilized, but the restriction remains in force. Petrenko has appealed to government officials for permission to export limited volumes of premium salt. So far, he says, there is little indication that the policy is about to change.

What instead of export?

Today, Petrenko is concentrating on strengthening the domestic market. Previously, the salt was sold only through small wholesalers and neighbourhood shops. Now it is stocked by major regional chains, including Rukavychka, Arsen, and Blyzenko. The product has also finally reached Silpo shelves. The ATB supermarket chain has offered cooperation as well, but orders of that scale remain beyond the operation’s current capacity.

Another revenue stream comes from selling brine to bakeries and large industrial clients, among them DTEK and Naftogaz of Ukraine. For these buyers, brine helps simplify processes and reduce costs. For the saltworks, however, such sales generate far less profit. Petrenko is negotiating a partnership that would allow Drohobych salt to be produced at another company’s facilities. “We supply the brine, they process it into salt, and sell it under our brand,” he explains. “In return, we receive ₴4 per kilogram in profit, plus ₴6 per kilogram for use of the trademark. We would also help them connect with distributors.” This approach could bring in up to ₴1.2 million without requiring the saltworks to expand its own production. The model benefits both sides: partners rely on Drohobych Saltworks’ raw materials and know-how, while the brand gains broader market access. These funds could be directed toward modernising the business. Petrenko also plans to develop the site as a medical, recreational, and tourist destination.

Guided tours are already available. Each month, the site welcomes around 1,600–2,000 visitors, generating an additional ₴50,000–60,000. The main challenge is turning short visits into longer stays.That requires new experiences and attractions. Plans range from a “salt laboratory” showcasing crystallisation experiments to hands-on baking workshops and even a museum dedicated to Drohobych sausage, as a reminder that local salt once underpinned the region’s meat-processing industry.

Health-related projects are also on the agenda. The team is exploring brine-based treatments, with plans for inhalation rooms, spa facilities, and outdoor brine tubs. Local medical institutions have shown interest and are willing to help create a free rehabilitation space for service members.

There are also plans for a park on the site. The saltworks owns 1.6 hectares of unused land that could be transformed into a public space. “We imagined concerts and festivals here, bringing life back to the territory,” Petrenko says. “As of now, though, there’s neither time nor money for that. Maybe next year.”

Still, his goal extends far beyond the domestic market. Oleh Petrenko wants Drohobych salt to become a global brand. “It could tell the story of Ukrainian past to the world,” he says. “And it could attract international investors to the saltworks. Not to chase quick profits, but to help preserve our heritage.”