In 2008, Kharkiv residents Vadym and Philip Gryshyn were working in the field of large-format printing. One day, they came across a cotton canvas usually used to create pictorial reproductions. The brothers used it to complete one of their orders. The material intrigued them, so Vadym and Philip showed it to their mother, Valentyna Ivanivna, who had long been fond of embroidery. She was the first to try embroidering a picture on the canvas with beads. This home experiment turned into a business idea and later into the company Abris Art, which became one of the first companies to offer embroidery kits on cotton canvas.

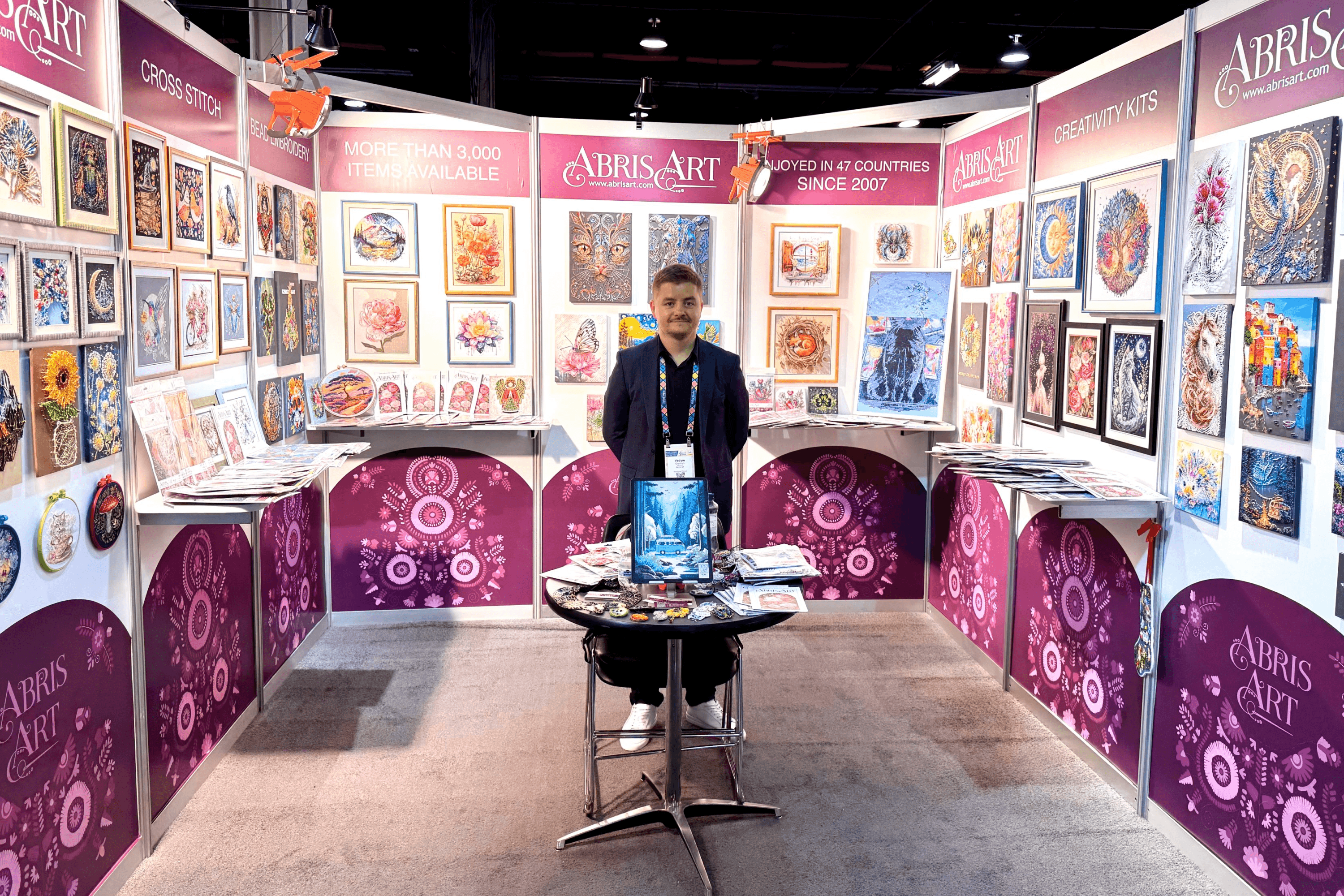

The company was previously based in Kharkiv, but after Russia’s full-scale invasion of Ukraine, the embroidery kits are now produced in Mukachevo. Abris Art exports its products to 20 countries on four continents. The business is focused on the B2B segment. The team consists of 15 Ukrainians. In 2024, the company reached a turnover of more than $1 million with a profitability of about 25%. YBBP journalist Roksana Rublevska spoke with Abris Art’s co-founder Vadym Gryshyn about entering the US and EU markets, popularizing bead embroidery around the world, and a new mobile app that is set to drive international expansion.

How did the idea for Abris Art come about?

In 2008, my brother Philip and I were working in outdoor advertising. One day, along with other raw materials, we purchased cotton canvas from a European manufacturer, which we used to print one of our orders. Usually, printing houses used this material for reproductions of paintings. The paint adhered clearly and richly to this canvas. It didn’t spread or lose its brightness, and the details were distinctly visible.

Our mother, Valentyna Ivanivna, had been fond of embroidery all her life — it was both a passion and a kind of therapy for her. She embroidered for herself, her friends, and her family, always paying close attention to the quality of the materials. Once, we brought her a piece of printed fabric — at first, just to show her. She decided to try embroidering on it, and after she was done, she was amazed: “It looks like a real painting, and it’s also three-dimensional!”

Then we realized that there was something more to it than just a hobby. That’s how the idea of turning printing material into a product for crafting was born. The three of us founded Abris Art, a company that later became one of the pioneers in creating kits for embroidery on cotton canvas. We had the technical base, and our mother provided the creative vision.

How did the company develop in the first years after its launch?

By 2010–2011, we had become an export company with a range of over 300 items. And we started with just one category — bead embroidery kits.

How much did you invest in the business? And when did Abris Art become self-sufficient and start making a profit?

This business is not capital-intensive: there is no need for expensive equipment, real estate, or large warehouse stocks. A similar business could be started with an investment of $30,000–50,000. We became profitable quite quickly, reaching the break-even point within two years. However, since we already had printing equipment from our outdoor advertising business, that also counted as part of our initial investment. Then everything depended on scale: for example, in 2010, we were already ordering $50,000 worth of packaging every month.

The business started turning a profit in 2009–2010.

When did you start expanding the team?

We started hiring people in 2009. At the same time, we began to build a full-fledged production facility and systematically scale up. Currently, 15 Ukrainians work for the company.

Did you immediately start creating kits under your own brand?

First, we proposed the idea of kits with cotton fabric to manufacturers who were already working in the handicraft market. After researching the market, we found that most of these companies were in Kharkiv, where we lived. We visited several of them — and were rejected everywhere. Each manufacturer already had its own technology, and no one wanted to change.

Then we decided: if they don’t see the potential, we’ll do everything ourselves and become the best on the market. We had our own printing shop and several designers who had previously made signs and stands. We tasked them with creating the first three designs for bead embroidery. At the same time, we found suppliers of beads and other accessories.

Who assembled the first kits?

The three of us did: Philip, our mom, and I. We packed the first kits by hand in the evenings after work, and then went around to embroidery shops, convincing them to try our product. The starter kits contained everything needed: an image printed on canvas, beads, a needle, thread, and simple instructions. Today, the range has expanded significantly — there are dozens of colors, new designs, convenient organizers, and a QR code that allows a customer to download a digital pattern for even greater convenience.

How did stores react to your product?

Several tried it and liked it. That’s how the first sales began. We put together five sets, then ten, then another ten. In 2008, we sold them for $20-30 per unit, depending on the design. From the very beginning, we adhered to a philosophy of quality: we used only good materials, and they cannot be cheap.

Was the key difference in your products? The fabric which resembled an artist’s canvas?

Yes, we didn’t use regular canvas, but natural art canvas with a printed pattern, which also served as instructions for embroidery. Part of the image remained printed, like a real painting, and individual elements were complemented with bead embroidery. This gave the works volume and aesthetic depth. We still maintain this approach today.

Have you been copied?

Yes, a few years ago, when we became visible on the market. There were several court cases, but it’s difficult to protect intellectual property in Ukraine. Despite this, in 2009 we obtained a patent for a utility model: embroidery on natural art canvas.

What does your production look like — do you manufacture the materials yourself or do you just assemble the final product?

We do not produce beads, needles, canvas, or printing inks. Our strength lies in creating the intangible component of the product. We develop original designs, patterns, instructions, and assemble kits — everything that determines their appearance and value to the customer.

The production facility currently operating in Mukachevo assembles kits from ready-made components according to production guidelines. The fabric is printed on industrial printers, cut, beads are added in specified proportions, and the finished kit is packaged. We carefully control each stage to ensure that the customer receives a high-quality product.

Have you always focused on the B2B segment?

Yes, this segment accounts for about 96% of our sales; we hardly sell to end consumers. Of course, we have a website and are represented on marketplaces such as Etsy and Rozetka, but this doesn’t even account for a tenth of our total sales. Our business is design, development, and production. Distribution and sales is our partners' business.

Regarding partners: how do you find them, and what percentage of sales do they receive?

At first, we looked for specialized offline stores that already sold handicraft goods and approached them directly. It was almost like in the movies: we would arrive, open a case with our kits, and convince them that working with us would pay off. That’s how we started. We began looking for distributors later, when we had more or less stable volumes of wholesale orders. The standard search model was “just googling it.” We used catalogs, association websites, participated in industry events and exhibitions. Depending on the country and purchase volumes, distributors receive 30 to 50% of the retail price.

How did you argue that it was profitable to work with you?

We emphasized the uniqueness of the base material. Our natural artistic canvas was stronger, more convenient for embroidery, and more durable than others. We found out that many craftswomen had a problem: cheap Chinese kits faded in just a year and a half, even without being exposed to direct sunlight. The reason is that the pigments are not designed for prolonged exposure to any light. We came with experience in outdoor advertising and used paints that can withstand five years in direct sunlight and many years indoors without changing color.

When did you start exporting your products to foreign markets?

Around 2011: we started looking towards the CIS countries then. Historically, Kharkiv has been a trading city and has been more oriented towards the east than the west. And as much as we hate to admit it, we focused on the Russian market.

What volumes are we talking about?

This is not an easy question, because it all depends on the format of the product, the size of the set, and the amount of materials: one set can cost €5, another €50. Therefore, we do not count in units, but in terms of profit and turnover. I don’t remember the exact figures, but in 2014 our turnover reached $0.5 million.

What happened in 2014 after the start of Russian aggression and the annexation of Crimea? Did you have stable export markets at that time, for example, in Poland or other European countries?

Until 2014, we had virtually no stable export markets outside the CIS. European sales were sporadic: sometimes we met buyers from European countries at trade shows in Moscow, or our Russian distributors sold our products in Europe. For us, this was not interesting either logistically or in terms of volume.

At that time, Russia accounted for about 90% of our exports among the CIS countries. There were no official bans on supplies to the Russian Federation in Ukraine — however, Abris Art reduced its trade with Russia by 50% and began a gradual expansion into Western markets. We visited European exhibitions, familiarized ourselves with local specifics, and translated the instructions. Then our first customers from Australia, the US, and various European countries appeared. However, another problem arose: our main product—bead embroidery—was not a typical type of handicraft for Europe and the US. Cross-stitch embroidery is the one traditionally popular there. Therefore, we had to explain a lot and adapt.

Was it difficult to enter European markets?

There were no complications with regulations, exports, or documentation, since these are light industry products. But Europeans didn’t understand our product and didn’t know what to do with it. The stores and distributors we worked with said, “We know what cross-stitching is. We use beads to make jewelry, but embroidering with beads is something new and risky for us. We don’t want to take the risk of ordering the first batches if we don’t understand how people will buy them.”

And you added cross-stitch embroidery to your product range?

Yes, and it actually became the beginning of a new venture for us. These are different patterns, materials, production technologies, and suppliers.

To minimize risks, we chose a hybrid strategy: to immediately build our own production and launch the product line through a private label model. We found a Chinese manufacturer who had already worked with the South Korean brand Dome and ordered the first batch from them — about a thousand units of each item. We translated all instructions and adapted the packaging and branding to our needs and target markets. This allowed us to test the product and sales channels without significant investment and with minimal risk before deciding to expand our own production. Only then did we begin to create our own collections and launch production in Kharkiv.

Were there any intellectual property risks when working with the Chinese manufacturer?

We signed a contract and agreed on exclusivity: we prohibited the manufacturer from making similar products for other customers using a similar design. We owned the design rights.

Which was the first country outside the CIS that you managed to introduce to bead embroidery?

It may not seem obvious, but the first was a client from Australia. He ran a family club and sent its members catalogs with hobby and handicraft products, taking mail orders. After seeing our products and assessing their quality, he offered to start with a small batch — a few cross-stitch kits and a few bead embroidery kits.

Over time, interest in bead embroidery grew, and gradually our product mix shifted: today, approximately 60% of our sales in this segment are bead embroidery kits, and only 40% are cross-stitch kits.

How did you shape your offer for Western markets?

We took our first steps in Western markets through cross-stitch embroidery, which was familiar to them, by adding several of our best-selling bead embroidery products to the batches. This helped our partners in Poland and Germany minimize risks: alongside the familiar product, they could test a new and unique one. This strategy worked right from the start in 2014–2015.

How did Abris Art’s business strategy change after 2014 and especially after 2022?

Until 2014, the Russian market was key, accounting for about 90% of our sales. After the annexation of Crimea and the start of the war in Donbas, we gradually reduced our dependence on Russia, and by 2022 it was already around 40%. This allowed us to save the business when, with the start of a full-scale invasion, we finally ceased all activity with Russia and reoriented ourselves towards Australia, the US, and the EU.

We quickly evacuated our families and team from Kharkiv to Mukachevo, leaving behind our production facilities, offices, and equipment. Funds from the company’s accounts were transferred to the Come Back Alive foundation. Production stopped, but thanks to agreements with partners to defer payments, we gradually began to emerge from the crisis.

It is noteworthy that since 2014, our Russian partners have asked us not to emphasize the Ukrainian origin of our products, as this was detrimental to sales. However, we have always insisted on our identity: we are a Ukrainian company, and we are proud of it.

What happened to production in Kharkiv after the full-scale invasion, and how did the team adapt?

At the time of the invasion, our production facility was located on the territory of a former Soviet factory, which was considered a military facility, so access to it was blocked. Only after a month were we allowed a short three-day visit, during which we managed to remove the main equipment for Abris Art and snEco and some of the finished products. Everything was transported to Mukachevo, closer to the EU borders. At first, it was just a hangar with items laid out on the floor, but within two months we started shipping orders, and in the fall of 2022 we resumed production. Demand came primarily from Ukraine: Ukrainians were looking for a way to relieve stress and took up embroidery. We decided to keep production in Mukachevo — our people are here, our responsibility is here, and we are close to the border.

What barriers — logistical, cultural, regulatory — did you encounter?

The biggest challenge was cultural differences. Christmas themes dominate in the US, traditional landscapes in Japan, Victorian scenes in Australia, and minimalist compositions in Europe. There are almost no regulatory barriers: our product does not require certification. Logistically, it’s also straightforward because the product is compact. The only issue is that the US imposes tariffs, but for Ukraine, they aren’t high — only 10%.

Who creates the designs for your sets? And are there any fashion or seasonal trends?

Our in-house team consists of artists, illustrators, and designers. We adapt our collections according to seasonality and the preferences of specific markets.

In which countries are you represented, and through which channels do you deliver?

We export to 20 countries on four continents: Europe, North America, Asia, and Australia. Sales channels are through local distributors who work with stores. We handle logistics through Ukrposhta, its EMS service, and Nova Post Global. We used to work with DHL and FedEx, but due to the full-scale war, these services are limited in Ukraine.

Is there competition in your business?

There is, but it’s not overwhelming. Most companies offer either classic cross-stitch embroidery or printed patterns without materials. Our format — a complete kit for bead embroidery on unique fabric — remains a niche product on a global scale. With the advent of marketplaces and globalization, competition has increased, but is now partially decreasing due to tariffs.

What is the margin of your business? Do prices differ in different markets and what are the logistics costs?

The cost of producing a single kit is about 40-50% of the selling price. The markup depends on the market: in Europe, prices are on average 20–30% higher than in Ukraine, and in the US and Australia, they are even higher due to logistics and the specifics of the local market. Delivery usually adds 10–15% to the cost of a batch for B2B customers, and this amount directly depends on the order volume.

How has the business changed over the past 17 years? And how do you manage to keep your customers' attention?

For the first 2–3 years, we worked mainly offline — on the domestic market and a little on the CIS market. Then we began to gradually expand: experimenting with our product range, new techniques, and entering marketplaces. Today, it’s already a brand ecosystem with a focus on customer experience. To keep their attention, we offer modern designs, interactivity, and technologies — QR codes, electronic diagrams, building a community, and encouraging repeat purchases. Over 75% of customers return after their first purchase.

What innovations are you introducing in 2025?

We were the first to offer digital diagrams for kits, and now we are working on a mobile app where you can track your progress and keep records. This year, we are launching a new category — painting kits. We want to rethink traditional “paint-by-number” kits to create stylish art objects with a pastel palette. The innovation will be highlighted by integration with the app: users will be able to save their progress, view their own gallery, and learn new techniques. At the same time, we are expanding our range with related products — embroidery hoops, holders, and everything else needed to make the crafting process enjoyable.

How many people embroider today — in the world of gadgets and AI? Is it possible to estimate the market capacity?

Today, millions of people do embroidery around the world, as confirmed by the sales volumes of major players such as DMC. In Europe, needlework often becomes a family tradition passed down from mother to daughter, while in the US it is part of therapeutic culture. Chains such as Hobby Lobby and Michael’s operate here with thousands of stores. Despite gadgets and AI, demand is not declining: people are looking for a way to get away from screens, relieve stress, and create something with their own hands. It’s a kind of yoga, only with a tangible result — a picture.

Do you see a threat from the growth of DIY communities on social media, where people share free patterns?

No, quite the opposite — we support such communities. Our customers receive an electronic pattern after purchasing a kit and are free to share it with friends or in groups. We realized long ago that there are two very different audiences. The first is those who look for everything that is free, buy the cheapest materials, and try to make something from what’s at hand. Our audience is those who value quality and comfort. They want to get everything in one kit: materials, a well-thought-out diagram, and a beautiful design. For them, handicrafts are a conscious expense for pleasure. We focus on such people.