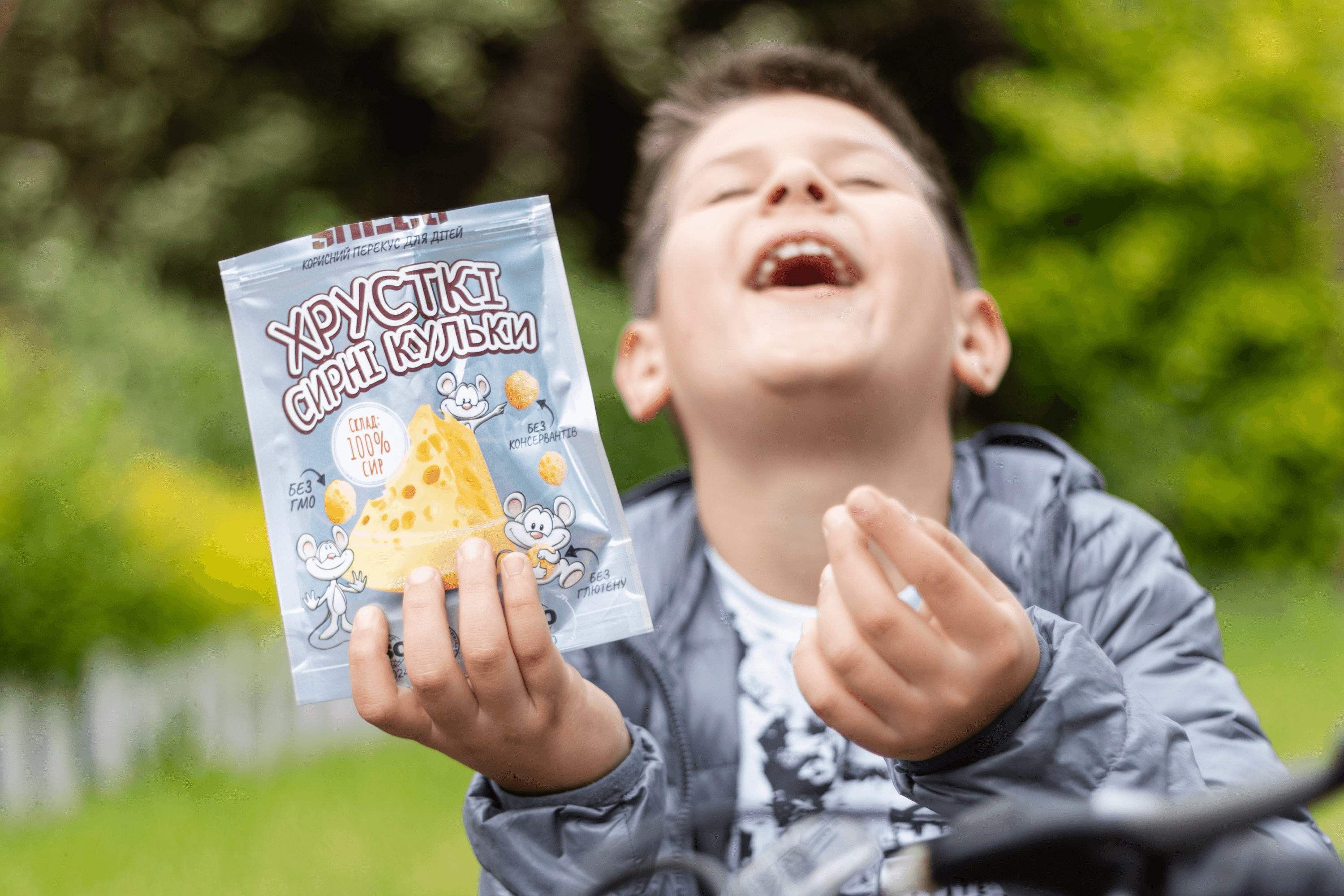

An engineer by education, 40-year-old Philip Grishin was born and raised in Kharkiv. Over 17 years ago, he and his brother Vadym launched a business making DIY kits for international markets. In 2015, during a trip to the U.S., the Grishin brothers tried dried cheese for the first time. With no such product available in Ukraine, they decided to create their own. In 2016, the snEco brand (under Prime Snack) was born.

The Grishins used a NASA-developed vacuum-drying technology for cheese. The first batches came with labels printed on a regular home printer. Today, snEco manufactures over 12 tonnes of product every month.

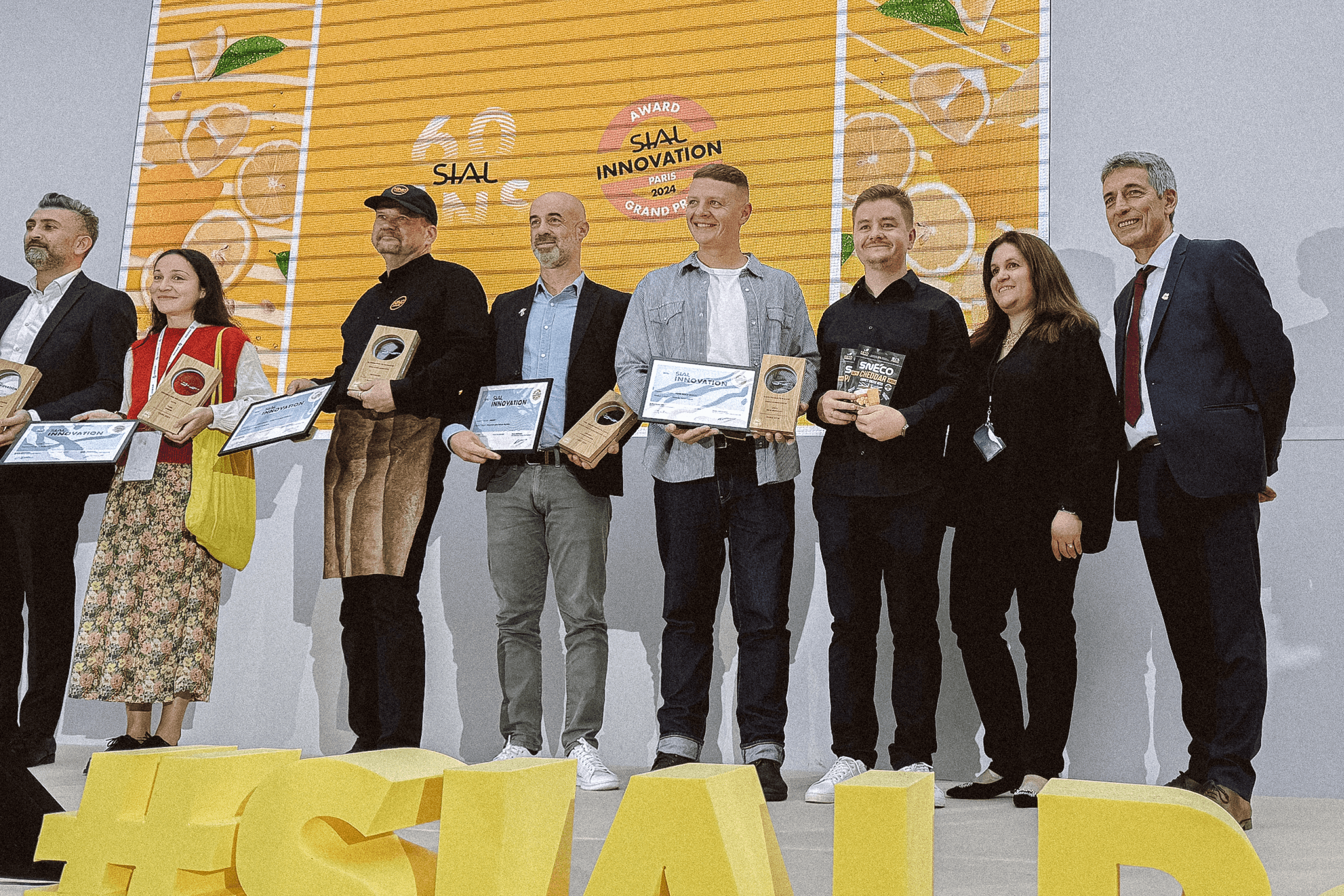

After the full-scale war began, production was moved from Kharkiv to Mukachevo. In 2024, snEco received the prestigious SIAL Innovation Grand Prix in Paris. In May 2025, another production facility opened in Slovakia. Today, snEco exports its products to France, Germany, Sweden, the Czech Republic, Japan, the U.S., and the UAE. The company works with all major Ukrainian retailers and doubles its revenue each year.

YBBP journalist Roksana Rublevska spoke with Philip Grishin about the cheese vacuum-drying technology, international expansion, and the business’s Ukrainian character.

How did you manage to dry cheese, given that it can’t withstand high temperatures?

How did you manage to dry cheese, given that it can’t withstand high temperatures?

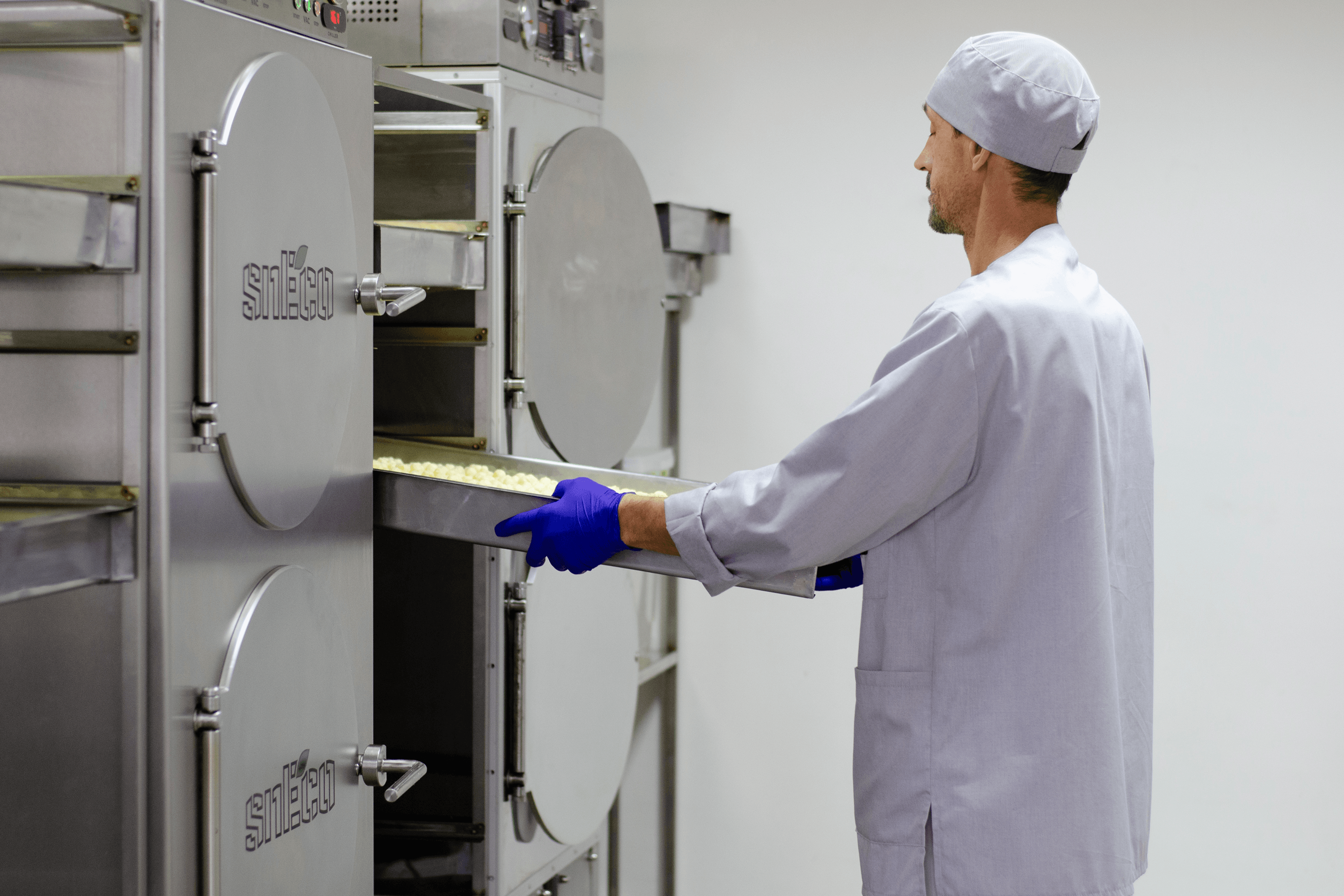

In the U.S., I became interested in cheesemaking. I took courses, visited dairies, and made cheese for myself and friends as a hobby. This passion merged with the idea of creating dried cheese. Together with Vadym, we spent almost a year searching for a technology, but for a long time, nothing worked.Traditional drying at 75°C and above melts the cheese, destroying its structure. We found a solution in microwave-vacuum drying, a NASA technology from the 1970s that works at 40°C. It’s essentially a microwave with a vacuum. At reduced pressure, water boils at just 27–28°C, which allows cheese to be dried at up to 40°C without losing taste, structure, or nutritional value.

You’re an electrical engineer by education. Did you adapt the cheese-drying equipment yourself?

In 2015, there was no suitable equipment on the Ukrainian market, so I created it myself using a combination of medical and food equipment. After a year and a half of experiments, we succeeded.

What problems did you face in the beginning?

We were getting cheese loaves, burnt product, odd shapes and flavours, but not the balls we wanted. In a year, we spoiled over 1,000 kg of cheese. The experiments continue even today. In recent months, for example, we have been working with blue cheese. It is difficult to dry, but we managed to adapt the technology and the equipment.

How does your product differ from the dried cheese by Moon Cheese, which you tried in the U.S. in 2015?

Their product is about 90% similar to ours, with the same principle and similar texture. But the difference is in the details: our cheese is better aerated and has a more even, convenient-to-eat shape — balls.

How did you scale production after the first successful experiments?

At first, we dried the cheese using a single unit, but later we found old equipment from a Ukrainian manufacturer dating back to the early 2000s, which we modernized for cheese drying. I handled all the technical solutions, documentation, development, and adaptation myself. Our advantage is that we still build the equipment ourselves, so we can scale without relying on suppliers and maintain full control over the technology.

Did you immediately see the project as a business rather than a hobby, with export potential?

Yes, it was a well-defined business project. In the first year, we invested around $70,000, covering rent, raw materials, and equipment. Cheese is an expensive product — a kilogram of quality cheese costs over $10. To produce 400–450 kg of dried cheese, we need to dry about 1,000 kg of raw cheese.

When did you first start selling cheese balls?

In mid-2017, we ran our first test sales through the OKKO gas station network, selling 200–300 packs per month. At that time, the snEco brand didn’t exist yet. Soon, we caught the attention of Groupe Bel (Bel Shostka Ukraine), who asked us to dry their cheese, about 700 kg per month. We took on the role of their contractor: they handled sales and marketing, while we managed production. This was our first serious contract, which propelled our growth and pushed us fully into the food industry.

We worked with Groupe Bel for about a year until they completely exited the Ukrainian market and sold all their factories. During that time, we noticed a major flaw in their marketing: the packaging only listed the manufacturer, Prime Snack, Kharkiv, without highlighting the uniqueness of our product and technology. This undervalued our innovation and taught us the importance of proper positioning.

So what makes your product unique compared to other protein snacks?

Our cheese has a very high protein content — ranging from 50% to 68% in our special fitness lines. But the main advantage is its convenience. It doesn’t require refrigeration and can even be stored in a car glove compartment.

Thanks to its ultra-low moisture of 3–4 percent, similar to the moisture content of stone, no mold or bacteria can develop in the product. Laboratory tests confirm a shelf life of up to two years. It’s 100% natural cheese, cut into cubes that transform into balls during the drying process.

How much have you invested in snEco over the years?

Including a loan, roughly $1 million. We continually reinvest our profits, and the loan has already been repaid. All of this is funded internally.

When did the company start turning a profit?

In 2021. Until then, all profits were reinvested in growth. Even now, we hardly take any money out, continually reinvesting it into the business. The break-even point was around $1.3 million per year. Once we reached that shipment volume, the business began operating profitably.

Who is your main consumer?

In 2019, we carried out a large-scale market study and clearly defined our customer profile: active people over 30 with a middle or higher income level who value healthy eating. That year, we received our first patents for both the product and the equipment and began systematic work on the brand.

What is it like working with your brother in a shared business?

Even a small difference, like 49% to 51%, could have damaged my relationship with Vadym, but having full equality at 50/50 became the key to our success. We managed to maintain balance. We have a clear division of responsibilities: my brother handles marketing and sales, while I oversee production.

We don’t interfere in each other’s areas. For example, I don’t even know the wholesale price of the product for retail chains. But we trust the results. This division has eliminated most potential conflicts. In 2017, we delegated operational management by hiring a CEO and a head of production.

How did the production structure change from 2017 to 2025?

In 2017, we started out practically in a single room, with no exaggeration, just three employees and homemade equipment. By 2019, the team had grown to 5–6 people, and by 2021 to 10–12. Today, about 40 people work at the factory in Ukraine and 14 at the one in Slovakia.

In 2021, before the full-scale invasion, we were producing just over three tonnes of product per month. By 2025, the combined output of the two factories exceeds 12 tonnes per month.

How did the full-scale invasion affect production in 2022?

Our facility was located in Kharkiv. At the start of the invasion, we lost access to both the office and the factory. The facility was on the grounds of an Interior Ministry site, which was immediately taken over by the military. Until May, we had no way of retrieving even seals or documents. Eventually, we arranged a three-day window to remove everything we could.

What exactly were you able to take out — equipment, raw materials, or finished product?

Only finished product. We didn’t even count the raw materials. Out of seven drying machines, we managed to take just three. The rest couldn’t be taken out in time due to the short window and the difficulty of dismantling.

What happened to what was left?

Two weeks after our evacuation, a missile strike hit the area, leaving nothing behind.

How did you rebuild your technical base?

We started making the equipment ourselves — from simple tables to our own patented drying machines. However, we don’t sell the equipment; we manufacture it exclusively for our own production.

Why did you evacuate production specifically to Mukachevo?

Our relatives lived there, and that’s where we relocated our families to ensure their safety.

You were offered the chance to open production in Poland or Slovakia, right?

Yes, there were proposals from food groups already familiar with our product. These were investors ready to contribute financially. But we still don’t take on external investments. There have been many offers — from large agribusiness groups to individual businessmen interested in taking a share of the company, but at this point, we see no need for that.

At that time, the choice was either to rebuild production on our own in Ukraine or start it at a new facility abroad with outside investment, which would have meant giving up the Ukrainian market entirely. Back then, there was a lot of uncertainty about the country’s future and the market. We do believe, however, that Ukraine will recover and the market will get back to normal.

From February to September 2022, you didn’t produce anything?

That’s right. We were relocating production, preparing the new facility in Mukachevo, and took out a bank loan of ₴10 million secured by personal property.

How did retailers react to your temporary absence from the market because of the war?

In the first two months, contracts were cancelled due to the lack of product. But most partners understood it was a force majeure situation. Some said “we’ll wait,” others said “pause.” We were able to re-sign contracts with most companies for 2023.

When did you produce the first batch after relocation?

In September 2022. It was 100 kg of dried cheese for the Silpo chain, which marked the restart.

How quickly were you able to ramp up volumes?

In 2023, we exceeded 2021 levels by 30%. In 2024, growth was already over 40%, and by the end of the year we expect to reach +50%.

In 2022, were you aware that your product wasn’t a necessity? Weren’t you afraid that demand might disappear during the war?

We were fully aware. But that’s when we recognized its strong positioning: it’s a backup product. It doesn’t spoil, requires no refrigeration, can be stored under any conditions, has high energy value, and can partially replace a full meal.

Do you supply your product to the military, since it’s convenient for field conditions?

Yes. However, we deliberately do not work directly with companies supplying the military because of tender complications and lack of transparency. Instead, we provide our product free of charge directly to the military through volunteers. Since the start of the war, we have donated over ₴500,000 to the Come Back Alive Foundation, and volunteers continue to include our product in soldiers’ food packages.

Which retail chains in Ukraine currently sell your product?

By 2021, our product was already sold in most large retail chains — except ATB. We ran a trial with ATB for about a year but realized our product wasn’t quite suited for that segment yet. Currently, we are present in nearly all large and smaller chains across Ukraine. The most recent significant step was launching in Metro, a chain with unique requirements. Metro only adds new products to its assortment that have already appeared in other retailers’ reports and demonstrate strong turnover and market share in their category.

You buy raw materials from European countries. Why not from Ukraine?

Ukraine doesn’t produce authentic aged cheeses like Gouda, Cheddar, Parmesan, or Mozzarella. Often, chemical ripening is used, which makes the taste very different.

Have you experimented with flavors?

Yes, with natural extracts like garlic, pepper, and herbs. But we decided against it — we kept only pure cheese. Recently, we introduced smoked Emmental (from Poland). We are also testing blue cheese and cheese-nut mixes: Gouda with hazelnuts, Parmesan with cashews, Mozzarella with walnuts.

When did you enter international markets?

We aimed for this back in Kharkiv, but the war interrupted our plans. Exporting animal products to the EU is complex and heavily regulated — let’s just say we weren’t exactly welcomed. In 2023, we spent eight months undergoing both domestic and European audits to obtain a license. Across all of Zakarpattia, we are the only company licensed to export these products to the EU.

Why is it so difficult to obtain a permit to export to the EU?

Europeans view Ukrainian regulatory bodies as too corrupt. They don’t want to risk public health by allowing products on the market whose quality they cannot verify.

Is it impossible to buy approval?

No. Success comes down to persistence and a willingness to adapt. About 95% of Ukrainian food legislation already aligns with European standards. You just have to demonstrate strict compliance with all procedures: record-keeping, internal controls, and staff training.

Which country did you first export to, and in what quantities?

Ireland. The first shipment was half a pallet — a few thousand packages. Today, we export 10–20 pallets per month, or 20–40 thousand packages. Each pallet holds 2,000 packages.

When did you open offices abroad?

We opened our office in Poland back in 2022 as part of our export strategy. Our production base for EU exports is in Slovakia, a country with a prime location, excellent logistics, and predictable regulations. We chose the city of Humenné because it is only 70 kilometers from our Mukachevo factory — this allows us to quickly synchronize operations between the Ukrainian and European facilities.

In May 2025, we obtained all the necessary permits and certifications to start production. We are still building the team — just three weeks ago, a commercial director joined to set up the sales department. Production hasn’t started yet, but the equipment is already installed. Current capacity is 5 tons of finished product per month, with plans to add another production line by year-end to reach 10 tons. The budget for the Slovak facility, at 5,000 kg per month, is approximately $0.5 million.

Currently, our Ukrainian site produces for the domestic market as well as for exports to the US, Japan, the UAE, and other Middle Eastern countries. The Slovak facility will serve as our full-scale base specifically for the European Union.

What is your distribution strategy in Ukraine, and how does it differ from your approach in Europe?

In Ukraine, many distributors don’t fully understand their role. They often see their job as purely logistical: pick up the product from the manufacturer and deliver it to a store, warehouse, or distribution center. But a true distributor is much more than just a transporter. They should actively promote the product, work with retail chains, stimulate sales, build relationships with stores, and ensure effective shelf presence. Without this comprehensive approach, the growth and sales of Ukrainian brands are significantly slowed.

In Ukraine, we essentially built our own distribution company because we work directly with stores. In Europe, our strategy is different: we seek strong distributors who can get us into large retail chains.

While Europe has many distributors, we try to work with one major distributor per country. Signing a contract with a distributor can take up to two years. One of our European distributors is the German company Monolith, which takes roughly 28–35% of the batch price.

Getting into European retail chains involves a category assortment committee that meets once a year (in some countries, every six months). New products are only considered during these meetings. So, introducing something new and competing with giants like Nestlé or Unilever requires considerable effort.

How can you compete with giants producing a wide variety of products?

Only with a unique selling proposition. It’s also important to offer retailers favorable terms so they can earn a little more on our product.

By favorable terms, do you mean a lower purchase price?

Yes, it could be a lower price or a higher margin — or various incentives such as marketing activities, promotions, and discounts that help support the product’s sales.

So, if you make a unique product that no one else currently produces in Ukraine or Europe, you also have to create ideal conditions for it to make it onto the shelf?

Unfortunately, yes. For example, if you make chips, everyone knows what that is, and the strategy is simple: make them tastier and cheaper. But when you create an entirely new product, you have to prove to the market that it’s needed and has the potential to compete on store shelves.

How many countries currently buy snEco products, and which ones?

At the moment, our products are sold in the USA, Japan, Slovakia, Poland, Germany, Ireland, Spain, the Czech Republic, and Hungary. We also made a test shipment to Canada — about 10,000 packages. After that, we usually wait about six months to see the product on shelves, evaluate demand and repeat sales, and only then discuss a permanent contract.

How can you break into closed markets like the U.S. and Japan, given the stereotype that everything’s already available and new products aren’t needed?

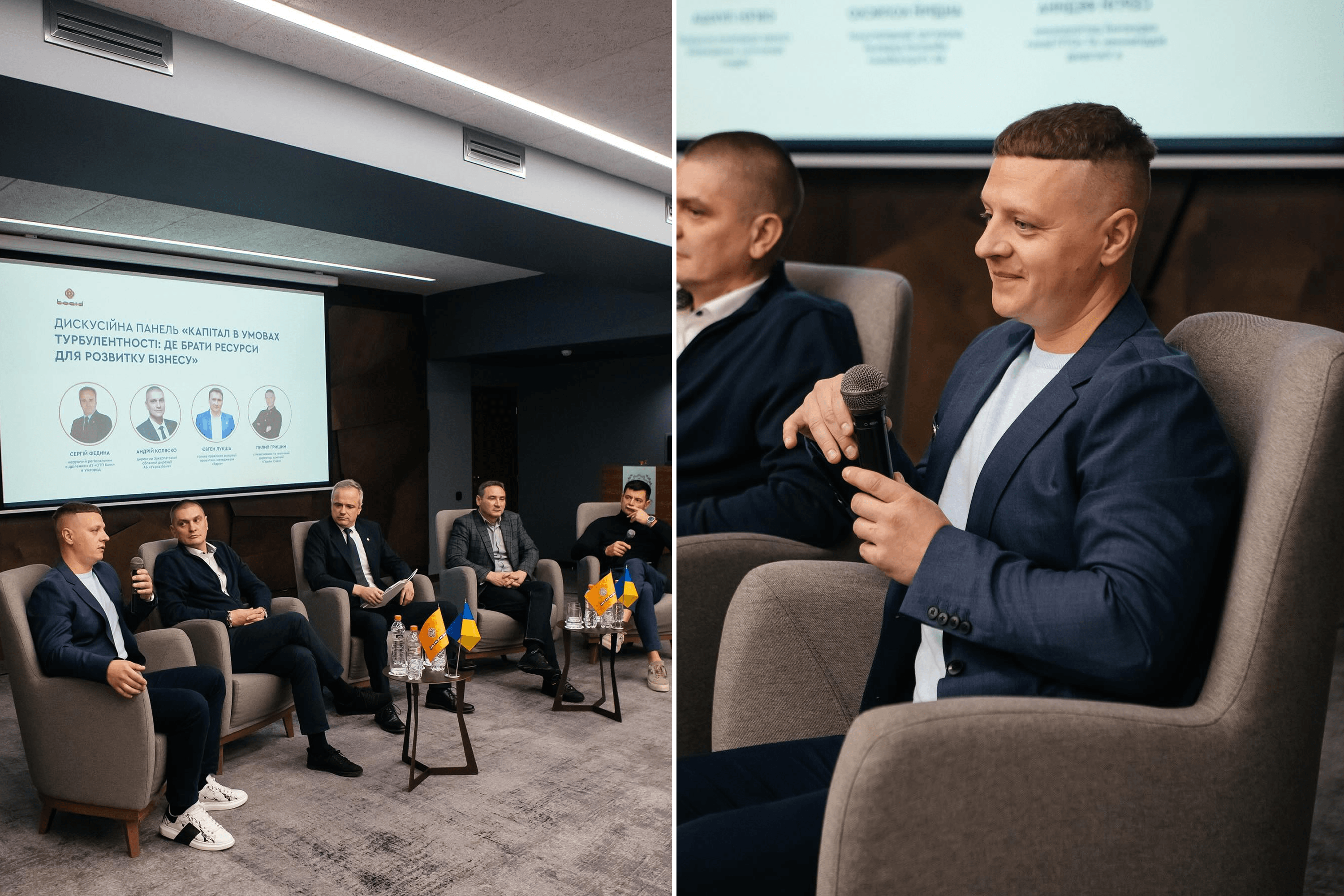

You can get in through trade shows and direct contacts with distributors or decision-makers at large retail chains. For example, in the U.S., we attended Fancy Food, and in Japan, Foodex Japan. Overall, we’ve been to 15 international trade shows, earning awards and recognition along the way. Notably, in 2024, our product became the first from Ukraine to win the Grand Prix for Innovative Product of the Year at the SIAL international exhibition in Paris. Closed markets are only accessible with a truly unique product.

Which markets are the toughest for you and why?

The toughest is the Ukrainian market because of its unpredictability and the lack of balanced conditions between producers, distributors, and retailers. Retail chains often call the shots, which makes operations more challenging. In Europe and the U.S., the market is more predictable: contracts are stable, rules are clear, and there’s a balance of interests among all parties. We haven’t left the Ukrainian market, as it serves as a testing ground and a place to refine our processes.

We also have a localization strategy for production: for example, we plan to launch cheese production directly in the U.S., Canada, or the Middle East, to be closer to consumers and avoid logistical challenges.

What are your financial indicators for 2025 — profit, turnover?

The year isn’t over yet, but our average monthly turnover is currently about ₴12–15 million. Our margins are above average, though I can’t disclose the exact percentage.

What are your main marketing channels?

In Ukraine, we handle promotion ourselves. In Europe, we plan to take a joint approach: we position ourselves as a global brand, while distributors promote the product locally.

In Ukraine, our main channels are social media and Google ads for brand awareness, but most sales happen through B2B rather than B2C. We allocate up to 20% of revenue to marketing and PR.

Every package, even those produced in Slovakia, is labeled ‘designed in Ukraine,’ highlighting the brand’s Ukrainian origin, even if the product is manufactured abroad.