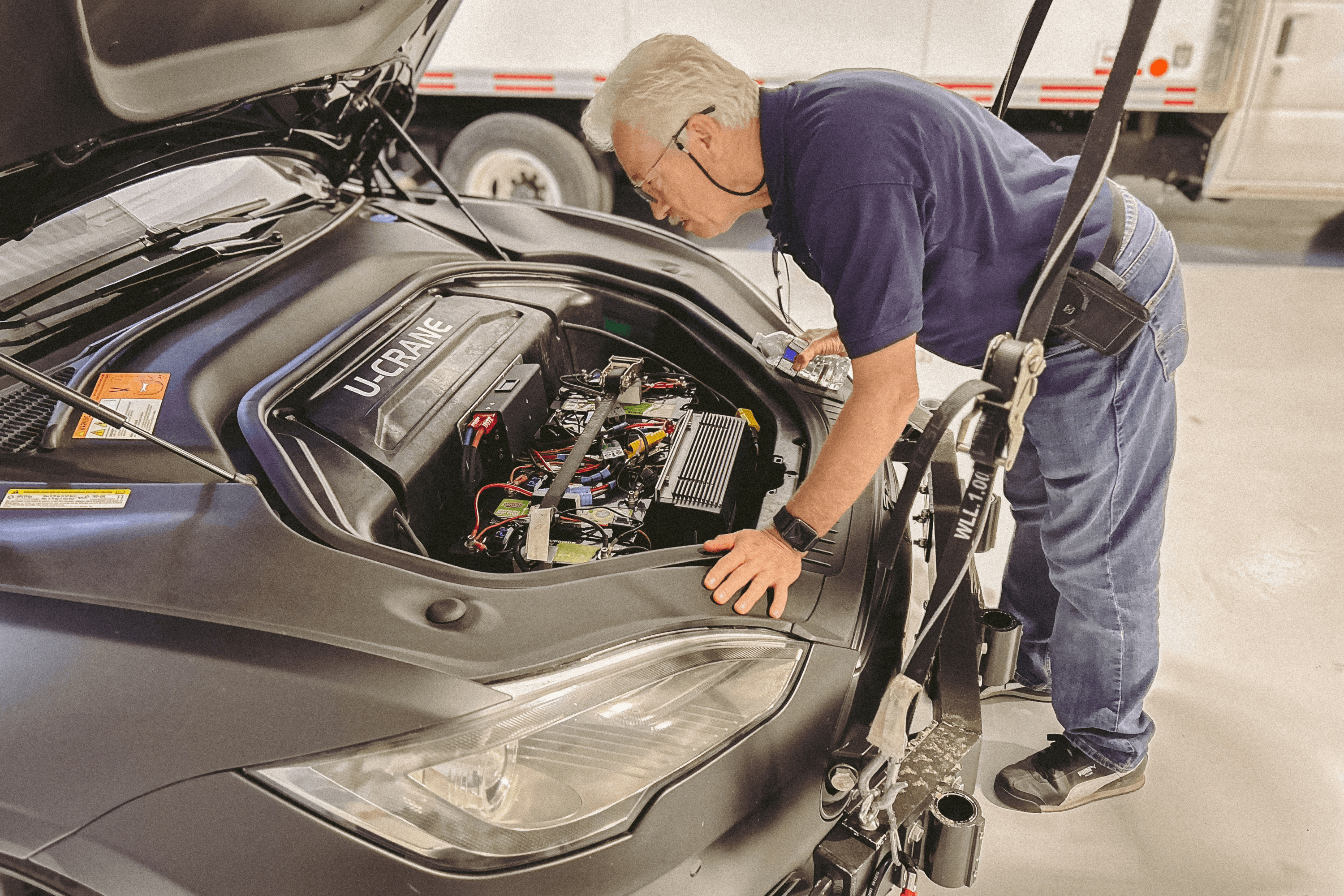

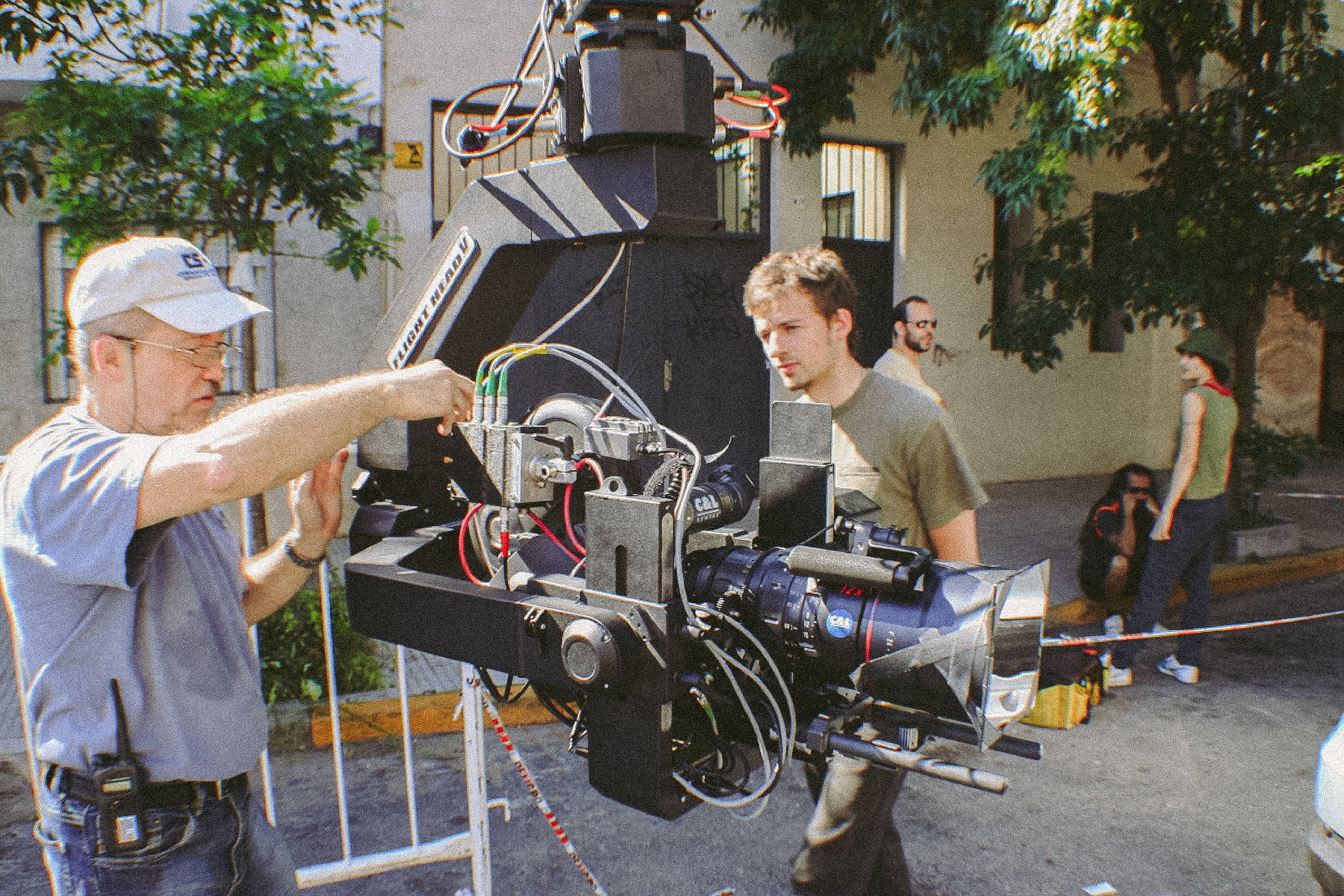

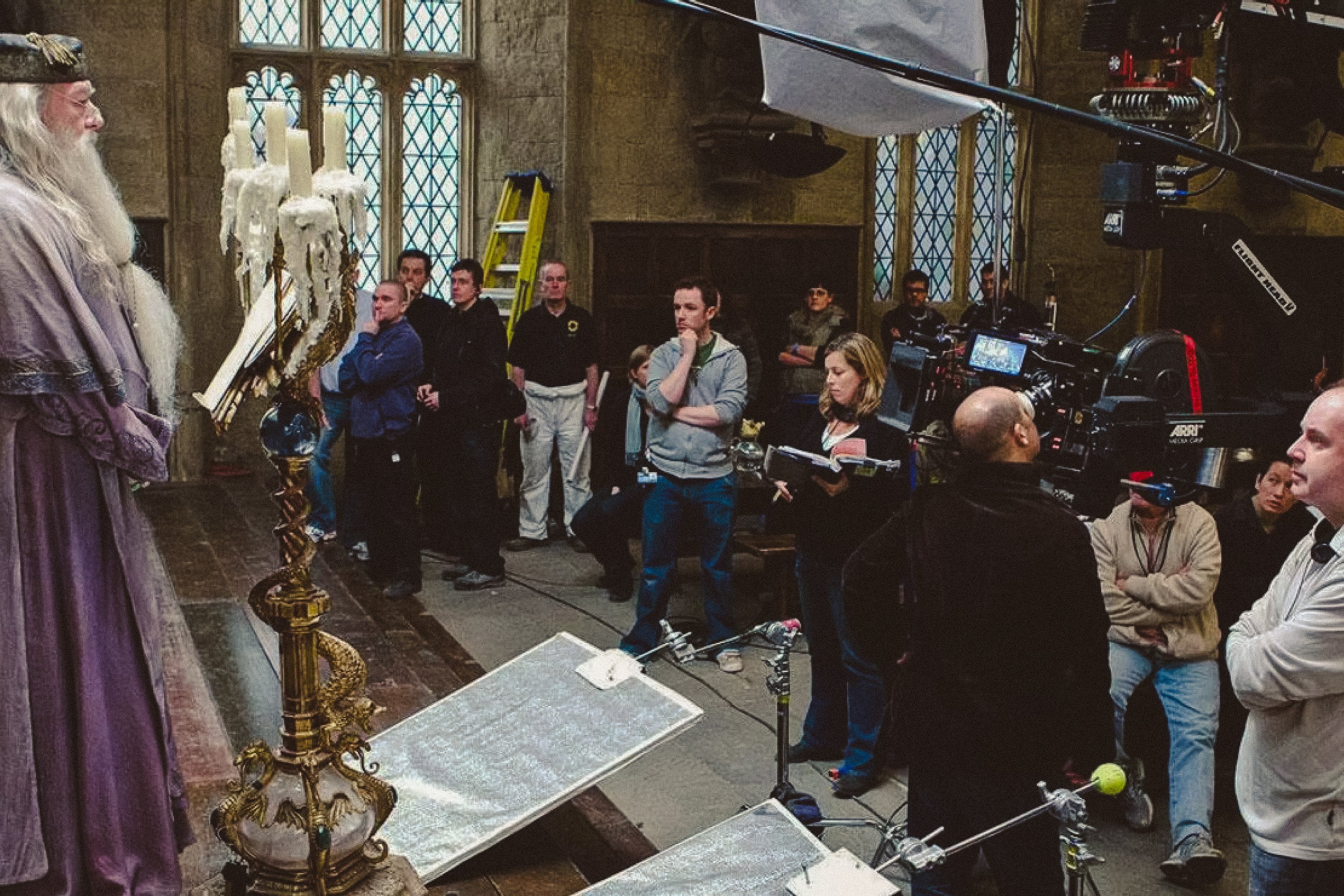

In 2006, the Ukrainian company Filmotechnic received an “Oscar” Academy Award for Technical Achievement. The Academy presented the award for developing the U-CRANE, a vehicle-mounted stabilized camera crane, and the gyro-stabilized Flight Head. These innovations transformed how filmmakers shoot dynamic scenes, allowing for crisp, stable footage, even at high speeds. It was a well-deserved recognition for Filmotechnic. Back in 1996, the company’s technology helped James Cameron shoot Titanic. But it all began in the early 1990s in Kyiv, when film engineer Anatolii Kokush, who had previously worked at the Dovzhenko Film Studio, founded a small engineering workshop with a bold idea to give cameras wings. Together with colleagues Yurii Popovskyi and Oleksii Zolotarov, created a unique system: a gyro-stabilized camera crane that could deliver steady shots from fast-moving vehicles — a first in the industry.

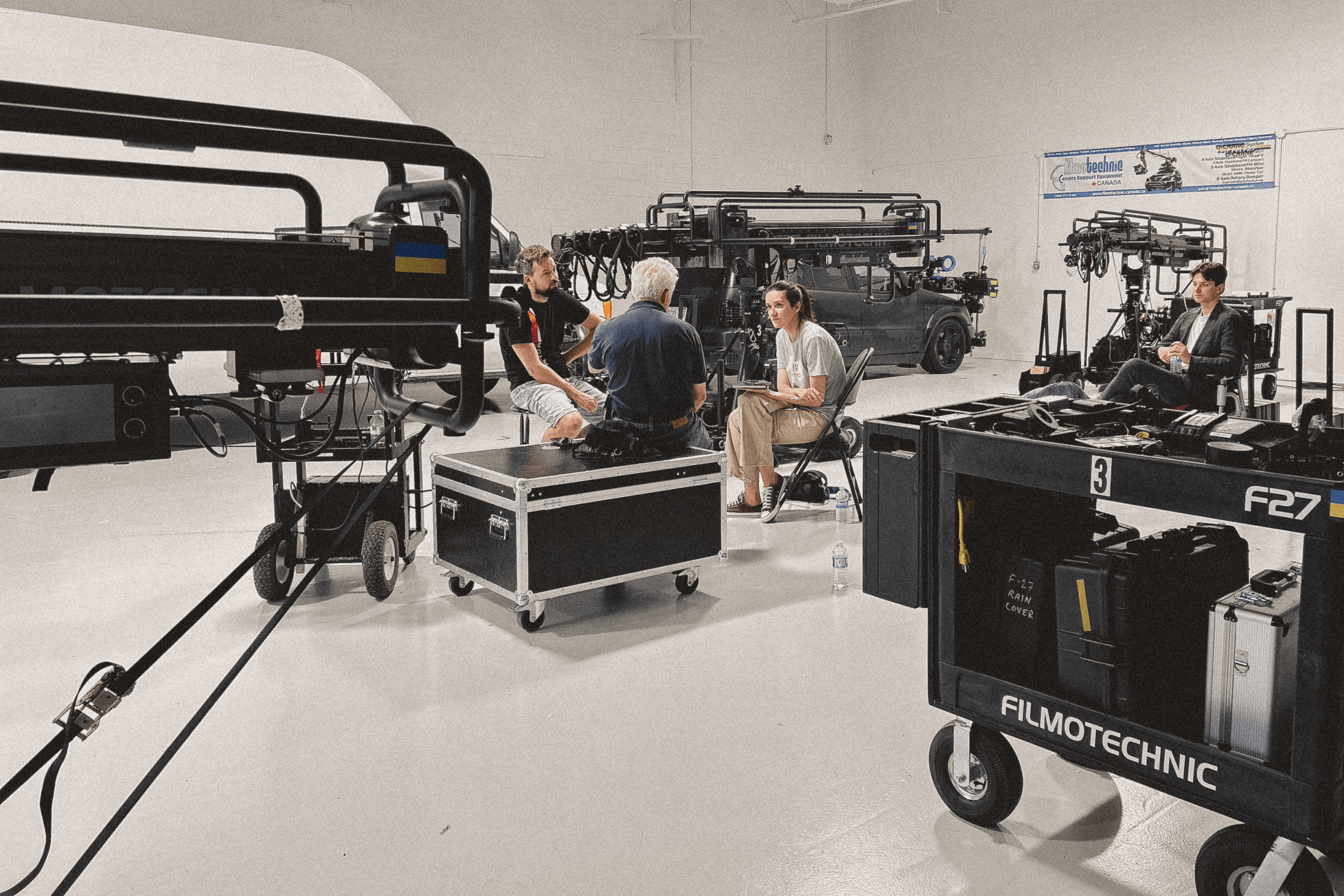

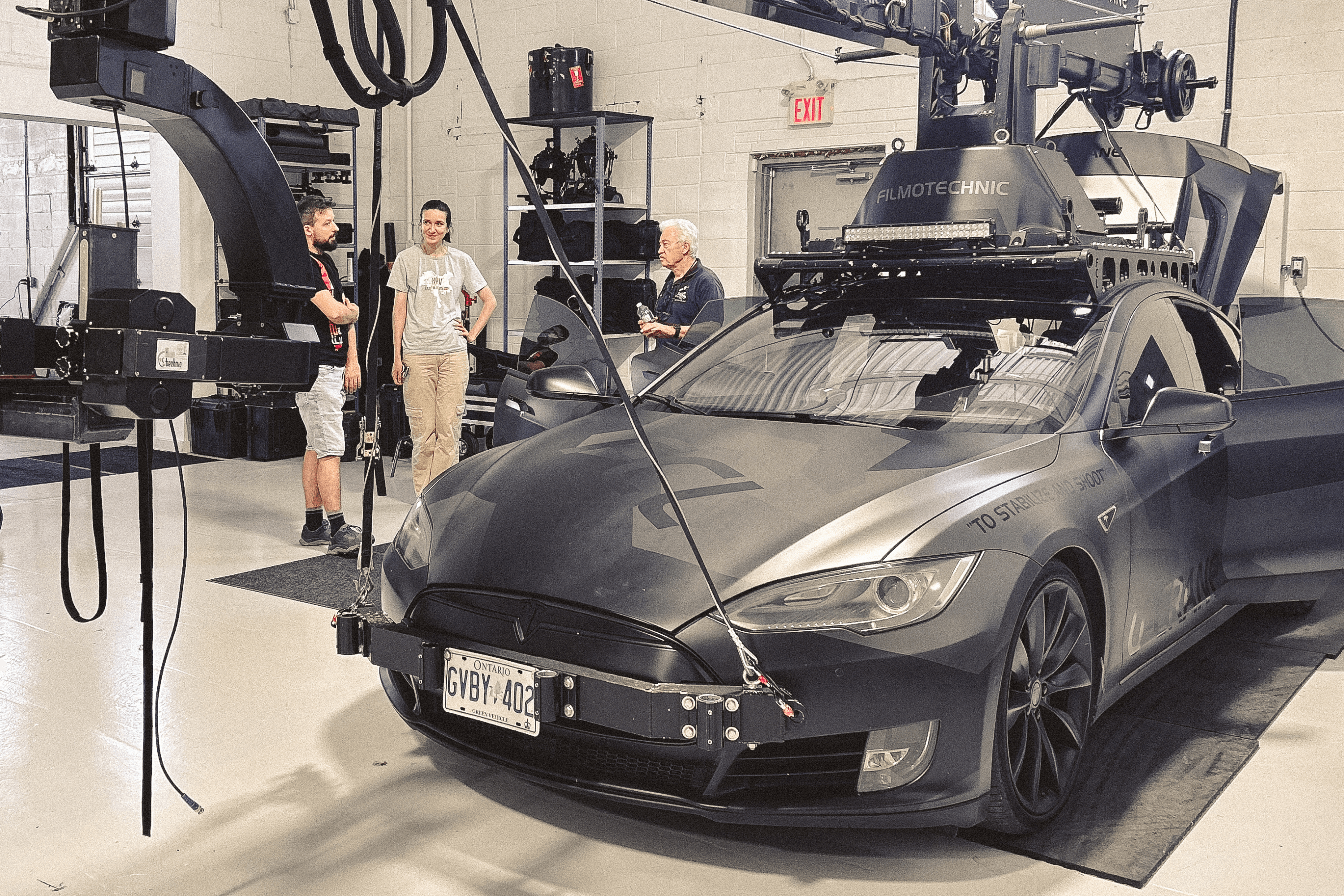

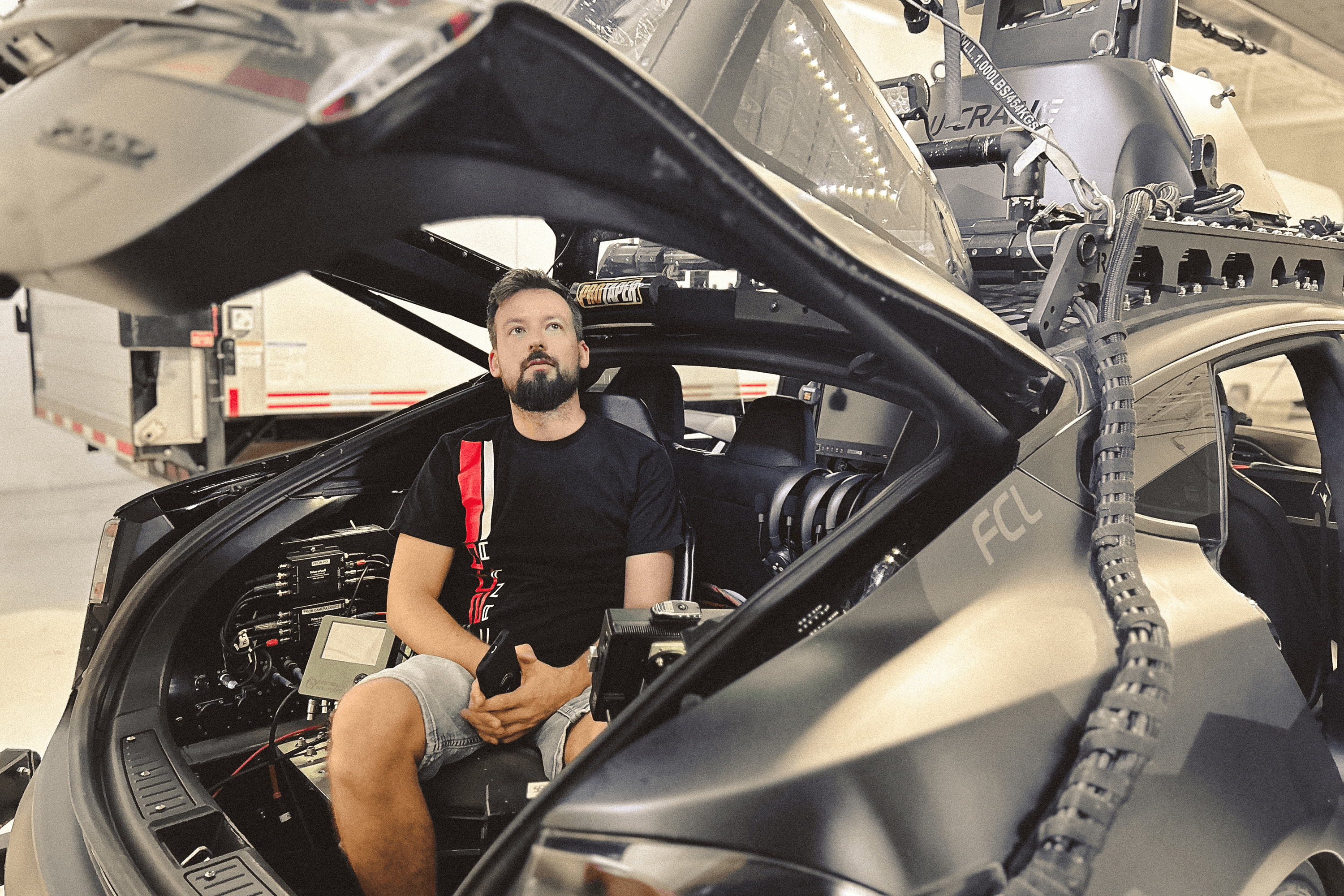

In 2007, Filmotechnic launched a Canadian branch. Today, its Toronto office showcases industry staples like the U-CRANE, Flight Head Apex, Technoscope, and Shock Absorber — equipment now found on major productions from Netflix to Warner Bros.

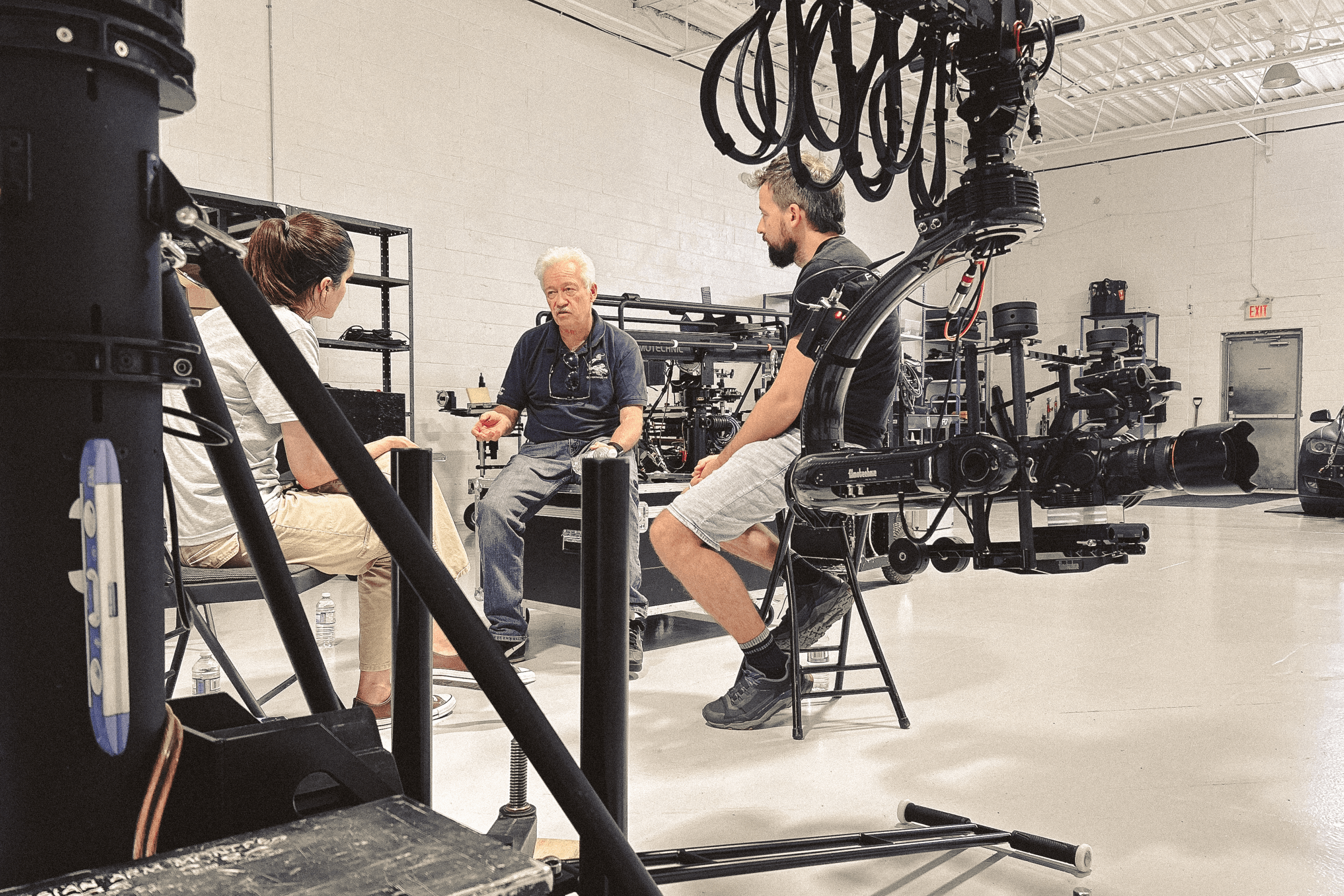

YBBP journalist Masha Zhartovska spoke with Oleksii Zolotarov — president of the company, cinematographer, engineer, and co-creator of the U-CRANE — along with his partner, Mykyta Zolotarov, to learn how the idea of the stabilized crane came about, how the Canadian film industry differs from the American one, and why in this business, reputation is everything.

Your main office is in Kyiv, and the equipment is still built in Ukraine — is that right?

Mykyta: Not quite. Today, we operate as an independent Canadian company, though we continue using the Filmotechnic name in different countries: Canada, the U.S., Japan, Europe, and across Asia, but our story and roots are firmly in Ukraine, and we still manufacture equipment there as well.

Some websites mention that Filmotechnic operated in Russia. Are you currently active there?

Oleksii: We started out in the Soviet Union. In September 1990, we went to our first exhibition in New York. A few months later, in December, we returned to independent Ukraine. We’ve never had a branch in Russia, only in Kyiv and Los Angeles, and those are independent companies.

In 1991, you brought your now-iconic crane to New York for your first exhibition. How did the idea of creating it come about?

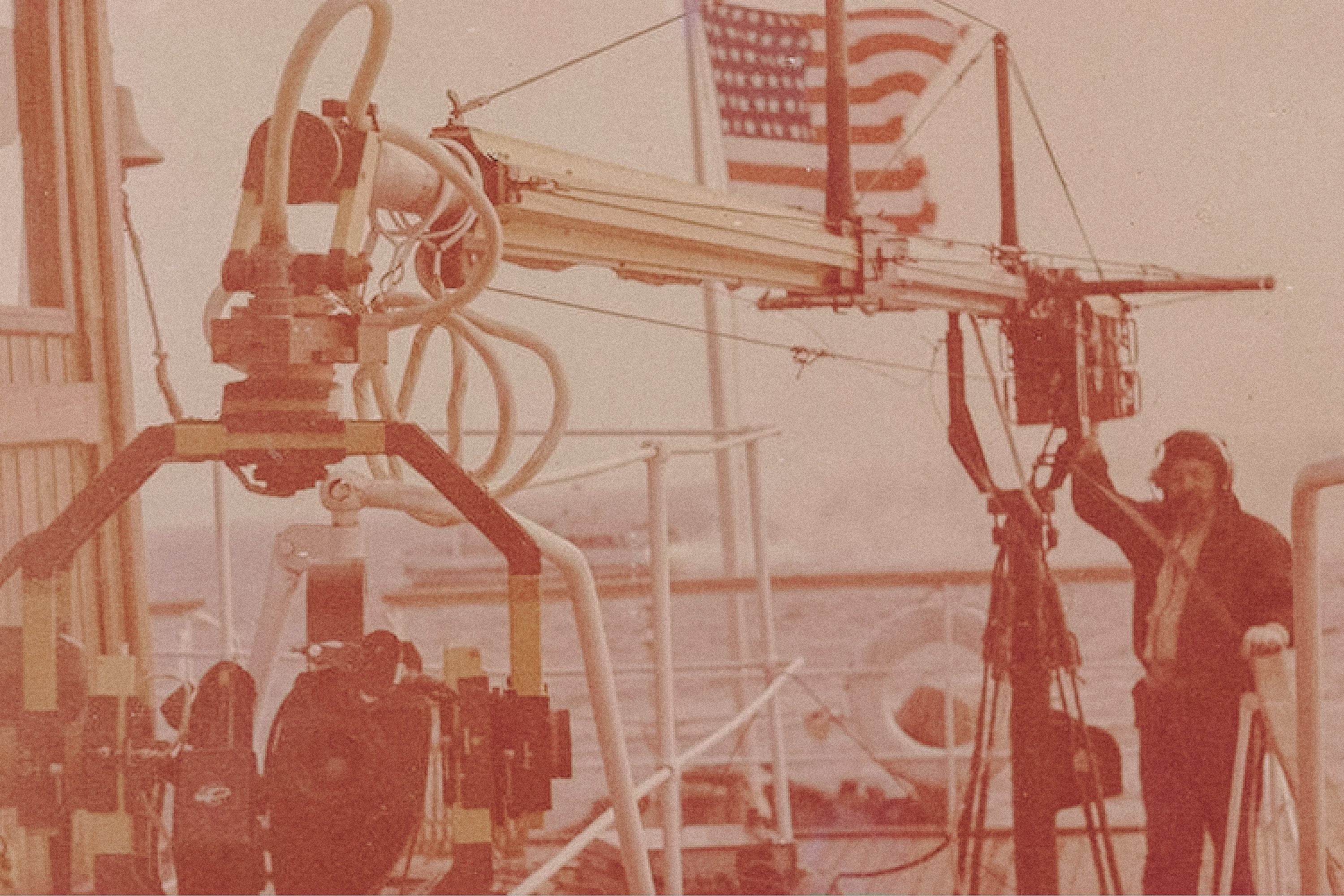

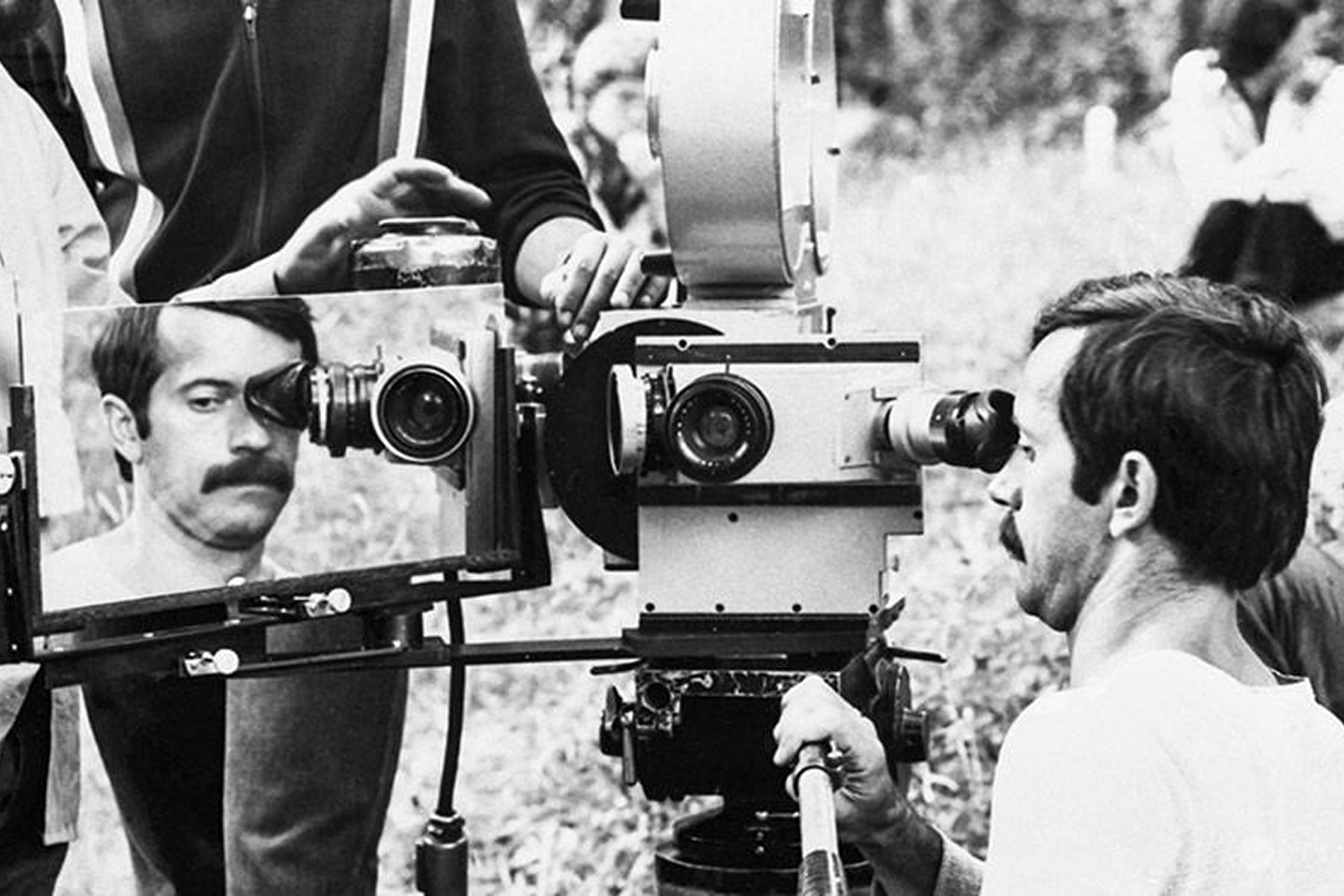

O: In the 1970s and '80s, I worked in the Soviet film industry. I started as a lighting technician and then became a camera assistant. In the Soviet Union, there was hardly anything to work with — just tripods, battered tracks, and a few cranes. But Dovzhenko Film Studio had something special: an engineering department that designed custom gear for film production. In the 1970s, one of our future co-founders, Anatolii Kokush, joined that department. It was essentially a research lab. In fact, all Soviet cameras like «Druzhba» and «Soyuz» were actually developed there. Mosfilm just copied everything, slapped their logos on, and claimed their engineers designed it. That lab eventually turned into a cooperative, and later into Filmotechnic.

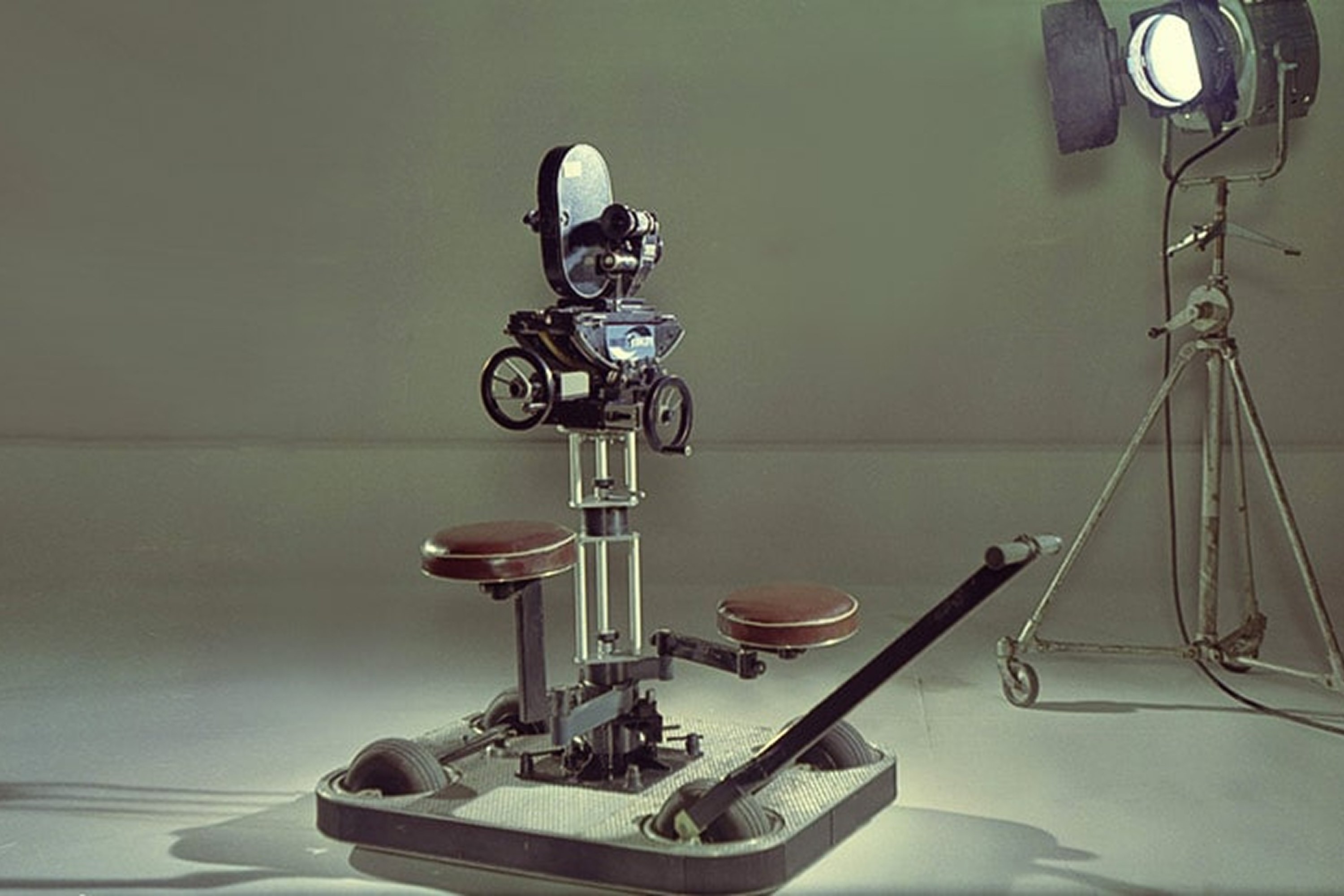

We built our first crane in 1984. These days, young people don’t even remember names like Tymofii Levchuk — a legendary director known for his war films. At the time, Kokush had secretly started working on a cascade crane. The head engineer opposed it, but Levchuk backed him. The team finished the crane, and it was put into production. Later, Kokush and I were having a beer, and he said, “You know, everyone wants movement. What if we put a crane on a car?” I laughed and called him crazy — how could you put two tonnes on a car? But Anatolii said, “We’ll build a smaller version”.

I had doubts — where would we get the parts? He said, “Let’s go to the scrapyard at the Antonov aircraft plant. We’ll find some metal and make it work.” So we grabbed a bottle of vodka for the security guard, who let us in. We got motors, scrap metal, and built our first crane. Roughly speaking, the idea was born over a bottle of beer.

How did you start your business in the United States?

О: In the early ’90s, we weren’t successful, the market was too conservative, and we didn’t have startup capital. We came back in 1996. The problem back then is still relevant today: film studio directors are cautious and won’t take chances on companies without a strong portfolio. In the case of Titanic, we honestly got lucky. Initially, they were using a Canadian system called Wescam, but it broke down after just two weeks. That’s when James Cameron told the producer, “Find something that works, I need results.” Our job was simply to make sure our gear worked. The producer said, “Send it”, and that was that. At the time, Hollywood had never seen equipment from the former Soviet Union. Ours was the very first to come out of Ukraine.

Andy Romanoff was in France with Jean-Marie Lavalou, the designer behind the well-known Louma Cranes. Lavalou had already heard about Filmotechnic and told Andy, “Listen, let’s go to Kyiv. You should meet them and check out how they work.” Romanoff was quite a well-known figure in Los Angeles. He’s retired now, but at the time, he worked at Panavision and was involved in all the major industry guilds. We showed him our cascade crane for the first time. I was still operating it with joysticks, everything here ran on joysticks at the time. In Ukraine, I worked using hand wheels.

Andy looked at the equipment and asked Anatolii, “Why does this technology exist here, but not in the U.S. or Europe? You need to get to the States. Bring everything — cranes, heads, whatever you’ve got — and go.”

He was a serious business person. At first, we worked through him, and later, we started Filmotechnic USA. When we received the Oscar, everyone was mentioned, we said, “A special thanks to our godfather, Andy Romanoff”. He was sitting there laughing. But the truth is — he was the person who got us started.

Did you speak English when you first went to the U.S.?

О: I graduated from university in 1985. I was lucky to have a great teacher there, but in school, I had a “C” in English. If my English teacher, who’s probably passed away by now, discovered that I speak English these days, she’d probably come back to life. I was the worst student in her class.

You mentioned that the American market was quite conservative, and you were coming in with unfamiliar Soviet-era equipment. How did you manage to break through? Did anyone dare to take a chance on you?

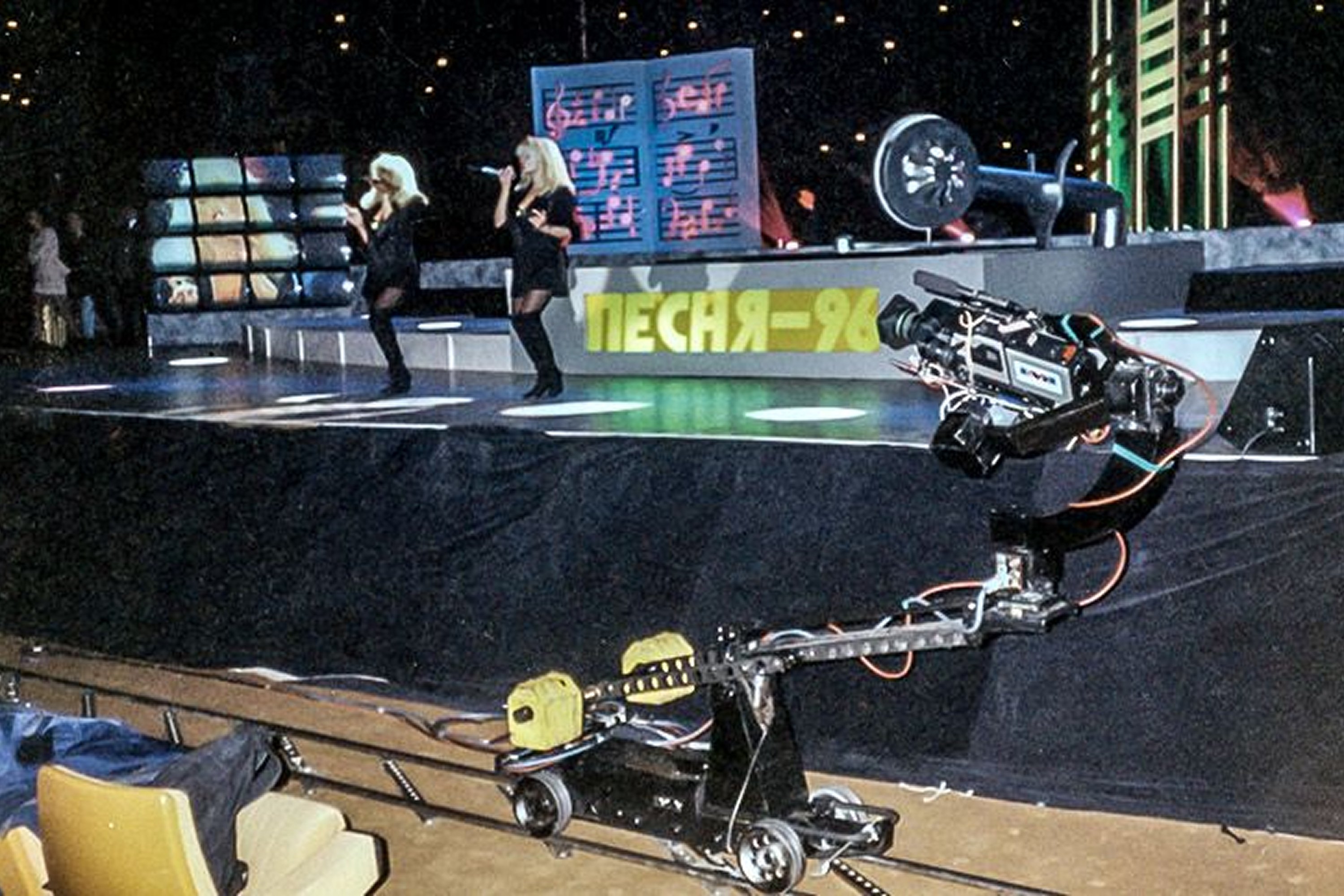

О: Our first major order came in 1996. The first rig we sent to Hollywood was nicknamed Red October. Andy was promoting us — he took us around to studios, demonstrated the equipment, and explained how it worked. Our first serious project was with a well-known director named Peter, I can’t remember his last name now. He was a big star in the advertising world, working on fashion and car commercials. He needed a dynamic shot that moved through a doorway at the start of a commercial. He initially wanted to use a Louma crane, but it was too short. We had the Cascade, 23 metres long, with 18 metres of active movement. For comparison, the Louma max was around 10. And from there, it spread like in a village: “Hey, what’s that you’ve got? Show us!” And off it went.

Then came another very well-known director, Sean Thompson. When he wants something, producers can pull their hair out, but he’ll get his way. That’s when we were introduced the ML-55 — at that time, only three of those prototypes existed globally.

Later, we got picked by Mr. Bean’s cinematographer, Francis Kenny. There’s a scene where Bean drives through Los Angeles, waving to people — that was our shot. They didn’t want to mount the camera directly onto the car, they wanted something more organic and natural. We did a test, the director watched it and said, “That’s perfect. We’re shooting tomorrow.” And that’s how it took off.

How long did it take to get established in the U.S.? The American market is known for being tough — it moves slowly, requires patience, and needs financial backing. Your partner helped with that support, but how long did it take to break even and start earning?

О: It took about a year to get things on track. We started working around mid-1996, and by the end of 1997, we had just started to break even. But then there was a serious downturn — things got really tough. A lot of our team ended up going back home.

At that point, we began training American crews — teaching them how to operate our cranes, use the joysticks, assemble and disassemble the equipment, and handle maintenance. Our core team returned to Kyiv, and the American technicians started working on their own. Slowly, things began to move forward.

I’d say by 1998 or 1999, the company had found its footing. From that point on, the business became more stable and started generating profits.

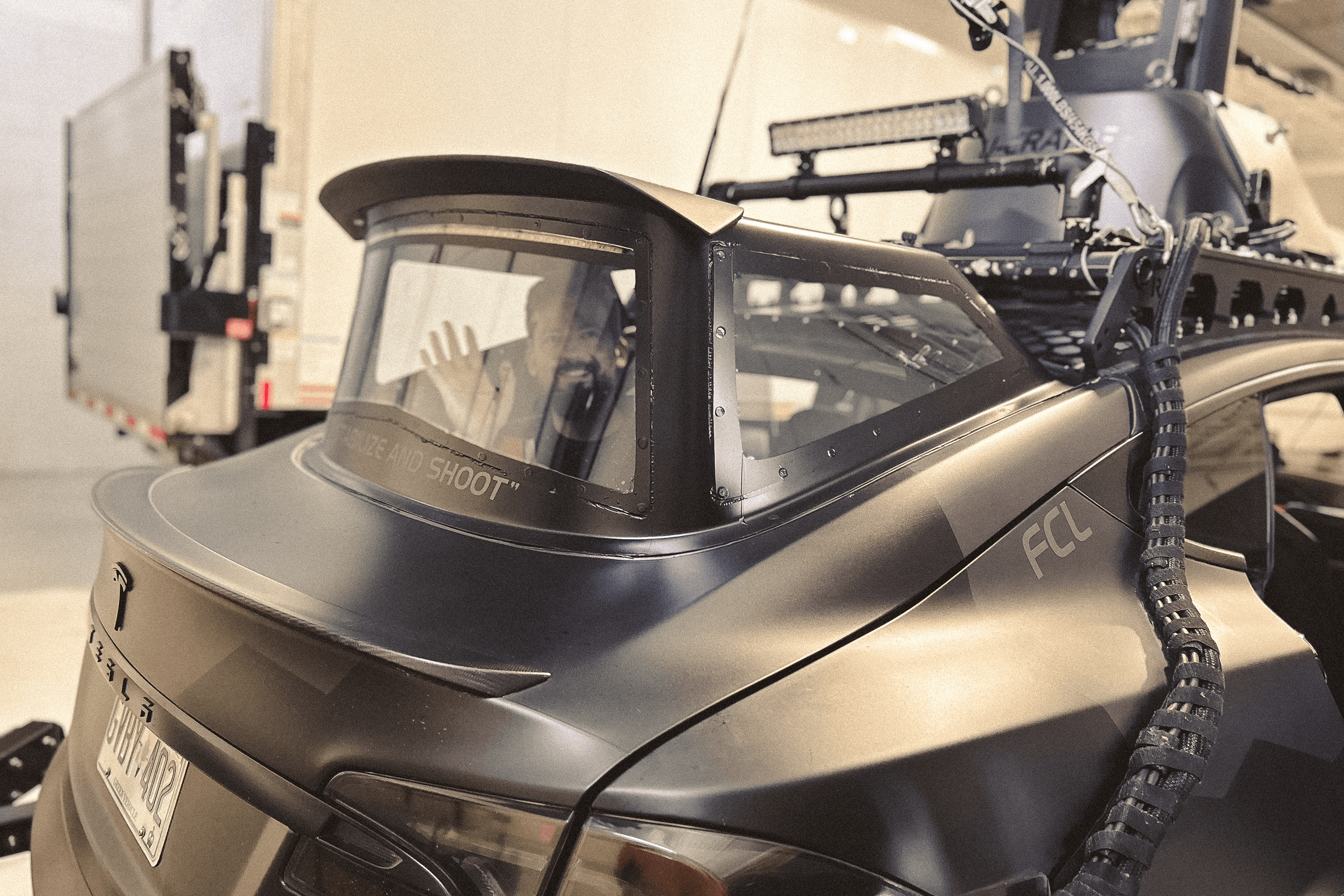

Did you really rename your crane from Russian Arm to U-CRANE?

М: Yes, and we’d been wanting to do it for years. The name Russian Arm never suited us. Initially, our crane was called “Avtorobot”. But over time, Americans started calling it the Russian Arm, and the name stuck for years. Later, even competitors began calling their cranes Russian Arm, even though they had nothing to do with Ukraine or Russia.

О: We had proposed changing the name as far back as 2014, but the Americans were against it — they said it was a well-known brand. But everything changed after the full-scale invasion in 2022. During a shoot in Los Angeles, someone saw the label Russian Arm on the gear and was ready to throw rocks at the arm or car. That’s when we said — enough is enough. Within three days, teams across the U.S., Canada, and Europe removed old stickers and replaced them with new ones. Since then, the equipment has officially been called U-CRANE.

What does Filmotechnic look like today?

М: In the U.S. and Canada, it works like a franchise, similar to Tim Hortons: each location can be owned independently. It’s the same with us — we own Filmotechnic Canada, and the Americans own Filmotechnic USA. The main company and manufacturing are still based in Kyiv. The equipment is either purchased or leased through sub-rental. We also do part of the upgrades and modifications on-site. Before the full-scale war, the Kyiv office had about 300 employees. Now, we’re down to around 120.

The company originally started operating in the U.S. What made you decide to open a branch in Canada as well?

О: I returned home to Ukraine in 1997, and in 2001, we found a legal firm in Kyiv that helped with immigration. While living in the U.S., I realized it didn’t really make sense to settle there — the path to citizenship takes about ten years. In Canada, the process is much faster, and you can travel to the U.S. freely. Plus, the U.S. market is extremely tough.

What differences have you noticed between Canadians and Americans?

М: Americans are flashy and a bit imperialistic. There’s a certain sense of superiority that comes across. Canadians, on the other hand, are more down-to-earth. There’s no Hollywood here, it’s all about service. Overall, Canadians come across as softer, more pleasant, but also more reserved. When we brought our equipment here, the reaction was something like, “What’s this? No thanks, I know my gear, I don’t need anything else.” We reached out to a lot of experienced operators, invited them to test out the joysticks and new controls. But only the younger ones came, the hungry ones to learn and grow. People had heard of us, but in the beginning, it was very tough. What really helped us get established in Canada was that it was the Americans who gave us a chance. It wasn’t like the Canadians said, “Oh, that looks cool, let’s give it a try.”

What’s unique about Canada’s film and commercial market? And where does Filmotechnic earn the most revenue?

М: Most of the big decisions still come from the U.S., the main decision-makers usually come from Los Angeles or New York, and the funding also comes from there. Even the majority of ad campaigns in Canada are routed through American agencies. There’s less creative work happening in Canada — Canada is more about executing the vision. At Filmotechnic Canada, we work across commercial projects, feature films, and occasionally television. For instance, we’ve filmed events like the Canadian Music Awards.

Our biggest revenue stream is advertising, especially in the past, when we focused mainly on automotive cranes and worked internationally, about 90% of our income came from commercial work. In 2019, new crane systems hit the market, but so did the competition. More affordable alternatives like Motocrane have significantly lowered the market value. Plus, automotive production budgets have been cut drastically, where shoots used to last for weeks, now they wrap in just a few hours.

How do you stay competitive? Are you planning to focus on something else moving forward?

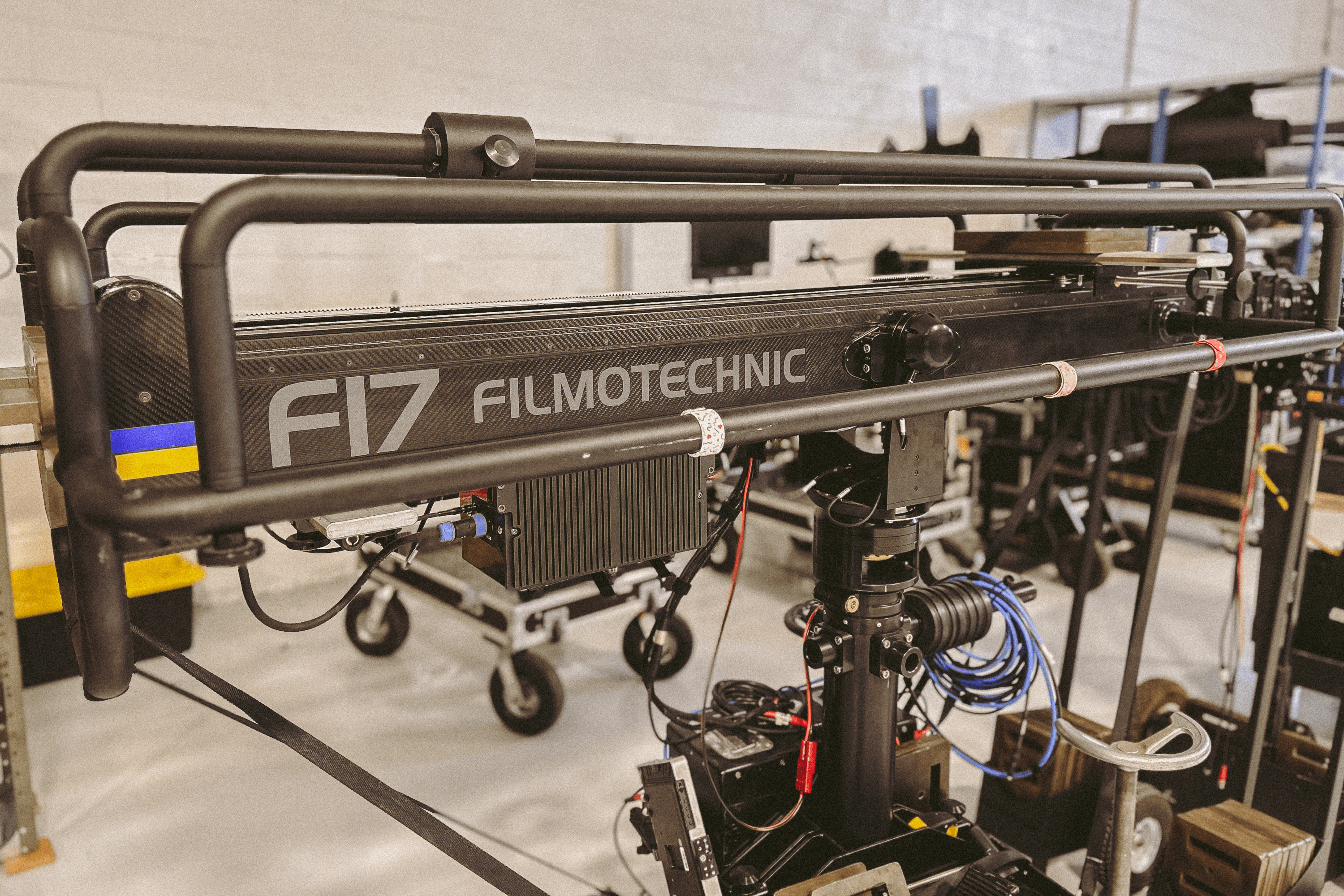

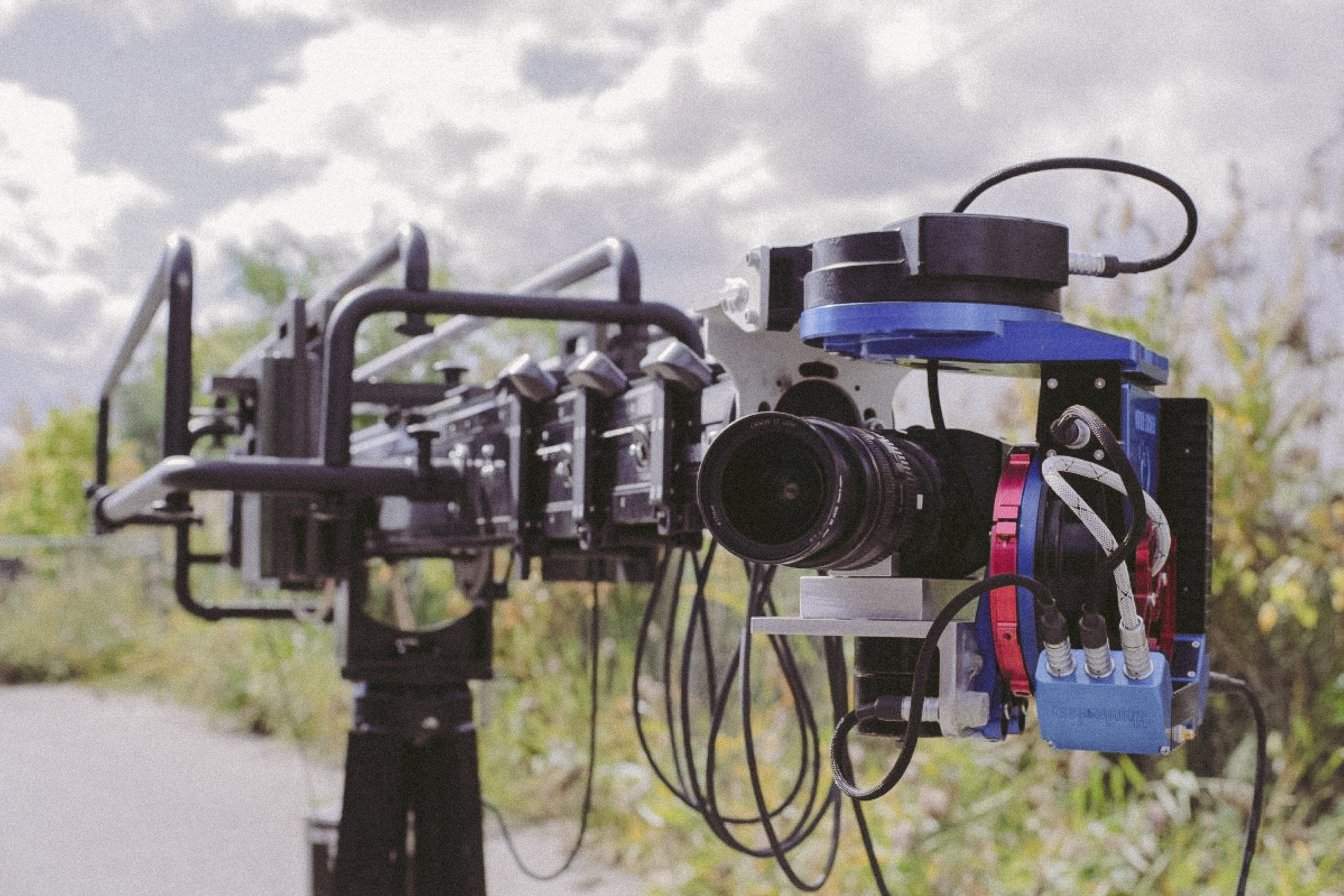

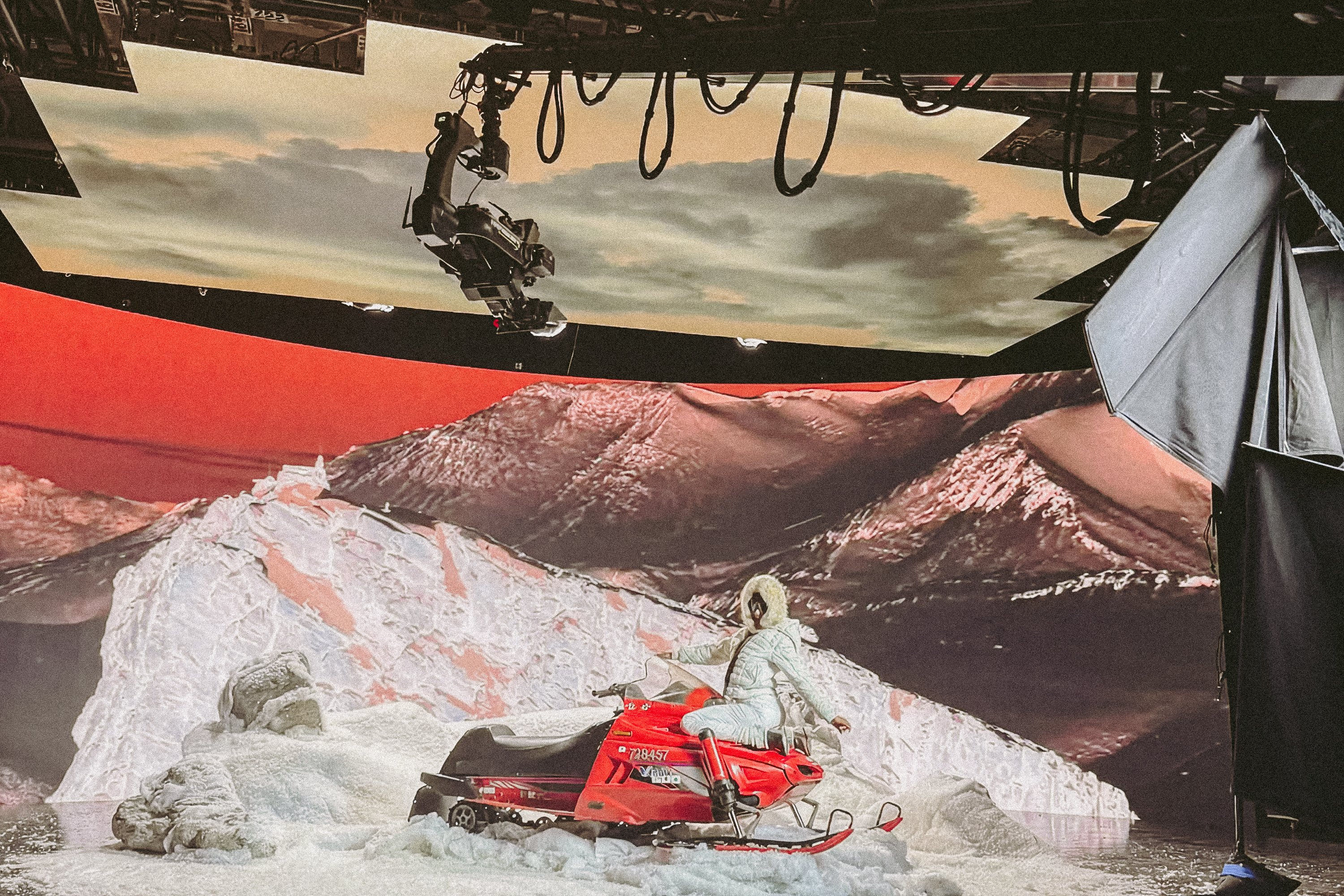

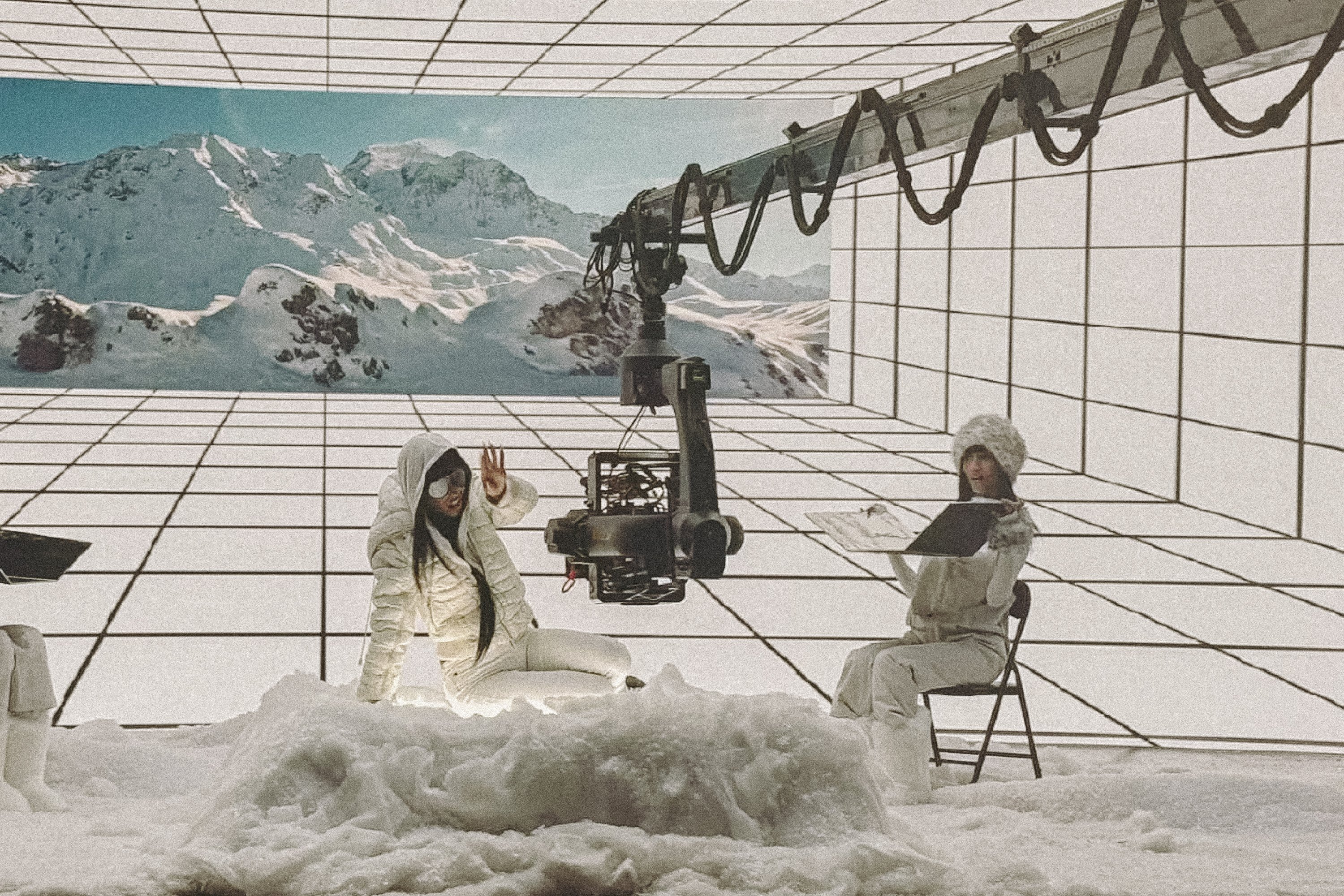

М: We’ve chosen to focus on telescopic cranes. If there’s a car commercial, great, we’re ready. But if there isn’t, what else do you shoot? Telescopic cranes are incredibly versatile. They work for studio shoots, documentaries, food commercials, insurance spots, pretty much anything.

Filmotechnic wasn’t the first to build telescopic cranes — there were already Luma, Technocrane, and Horst from the Czech Republic and Poland. But we were the first to use carbon fibre, which made our cranes lighter, smaller, and more affordable. Our telescopic crane has a 27-foot reach, while Technocrane offers 30 feet. But their base is five times larger, which makes it bulky and expensive to move and rent. With our crane, we’ve been able to take over the advertising segment completely. It’s even been used to shoot the last three seasons of the Titans series. One crane like that can cover an entire production and that’s enough to get the job done right.

Would you say your reputation is stable now?

О: Definitely. We’ve been in the business for over 20 years.

Do you have many returning clients who work with you regularly?

О: In the commercial space, yes — several companies work with us consistently.

М: But the industry is very dynamic. Some clients have been with us for years — they know our work and trust us. Others are always on the lookout for something new. This is especially true in film: a team might collaborate with us for 10 years, then a new idea comes along, and someone else steps in to give it a go. It really depends. We’ve found commercial advertising easier to work in, the film side is tougher, especially when there’s less being shot these days.

How would you say business is going right now?

М: I’d rather not give exact figures, but budgets have definitely tightened. We need to collaborate. We have our specialization, other companies focus on cameras, lighting, and so on. The key is working together when small companies team up to offer full-service solutions.

Are you actively promoting your services these days?

М: No, not really. Traditional advertising just doesn’t work in our industry. I’ve tried running Google campaigns, but the industry is far too niche. Everyone knows each other. I have around 6,000 followers on Instagram — mostly cinematographers, DPs, and directors. If I need to share something, I post it there and word spreads quickly.

What works far better is building community. We hosted something called Meltdown — a casual gathering for operators with cranes, coffee, beer, and drones. Other vendors joined, and it turned into a mini showcase. Producers and cinematographers came by, and that’s how we networked.

But there’s an issue — many older operators stick to what they know, they’re not interested in exploring new tools or workflows. The ones who are engaged already know us and follow what we do. But some are indifferent — no matter how much you innovate, they simply won’t care. Even in production companies where people are familiar with us, it’s not uncommon to hear, “I didn’t even know this kind of gear existed in Toronto,” even though we’ve been here for 20 years. By now, we really should be on everyone’s radar.

Do people in Canada know that this is a Ukrainian innovation, especially in recent years? And has that helped the business at all?

M: Absolutely, especially after we changed the name. Even before that, there was some awareness, though at times people assumed it was old Russian tech. Does it help with business? Not directly — it’s not like someone hires us just because it’s a Ukrainian invention. Maybe only briefly, at the start of the full-scale invasion, when we were fundraising for the Ukrainian Armed Forces.

Do you feel that you’re recognized in Ukraine?

M: Definitely. In Ukraine, people know who we are, and we’re still active there. Whether they know about the Canadian operation, probably not. But the company is a leader in the field — the oldest and largest in the industry.

How did Donald Trump’s presidency affect the local film industry, considering Canada has always provided production services?

M: It’s tough to pin down a direct impact. The thing is, film isn’t a physical product, so you can’t just slap tariffs on it like steel or cars. And when it comes to streaming and subscriptions, the whole model is even harder to regulate or tax. One major issue is that Trump didn’t understand how the film industry works or what’s needed to help it grow in the U.S. His policies didn’t address the core problems in Hollywood. Like, how hard it is to get permits and shoot in Los Angeles. That’s why productions moved elsewhere. And really, the only thing you could tax would be movie tickets — but attendance is already declining. Add more taxes, and it’s game over. If you notice, he stopped talking about it, and I don’t think he’ll pursue it again.

Canada offers production incentives and infrastructure that the U.S. just can’t match. Ontario, for example, has had support systems in place since the 1980s. Even materials are cheaper — most sets are made of wood, and lumber here is more affordable. We spoke with producers from a major U.S. streaming platform, and they admitted their U.S. budget couldn’t compete with what Canada could offer.

What are your plans for the company’s future — are you considering growth or possibly selling it?

M: We’re constantly exploring partnerships and collaborations, and we’re in ongoing talks with different players in the industry. But honestly, it’s a tough question to answer right now. Between the fallout from COVID and the two Hollywood strikes, the industry’s in a difficult place — budgets have been slashed. So for now, there’s no clear direction, just continued adaptation.